Degaser 190

By: Scottish Chemical Industries| Price | Available on request |

| Colour | Blue |

| Density | 1.70 - 1.90 grms/cc |

| Moisture | <0.05% 50 grms / 250 grms / 500 grms tablets |

| Category | Degasser and Fluxes |

| Manufacturer | Scottish Chemical Industries |

| Min Order Quantity | 500.00 KG |

| Delivery Lead Time | 7-10 Days |

| Place of Origin | Maharashtra, India |

| Supply Ability | Customization on Requirement |

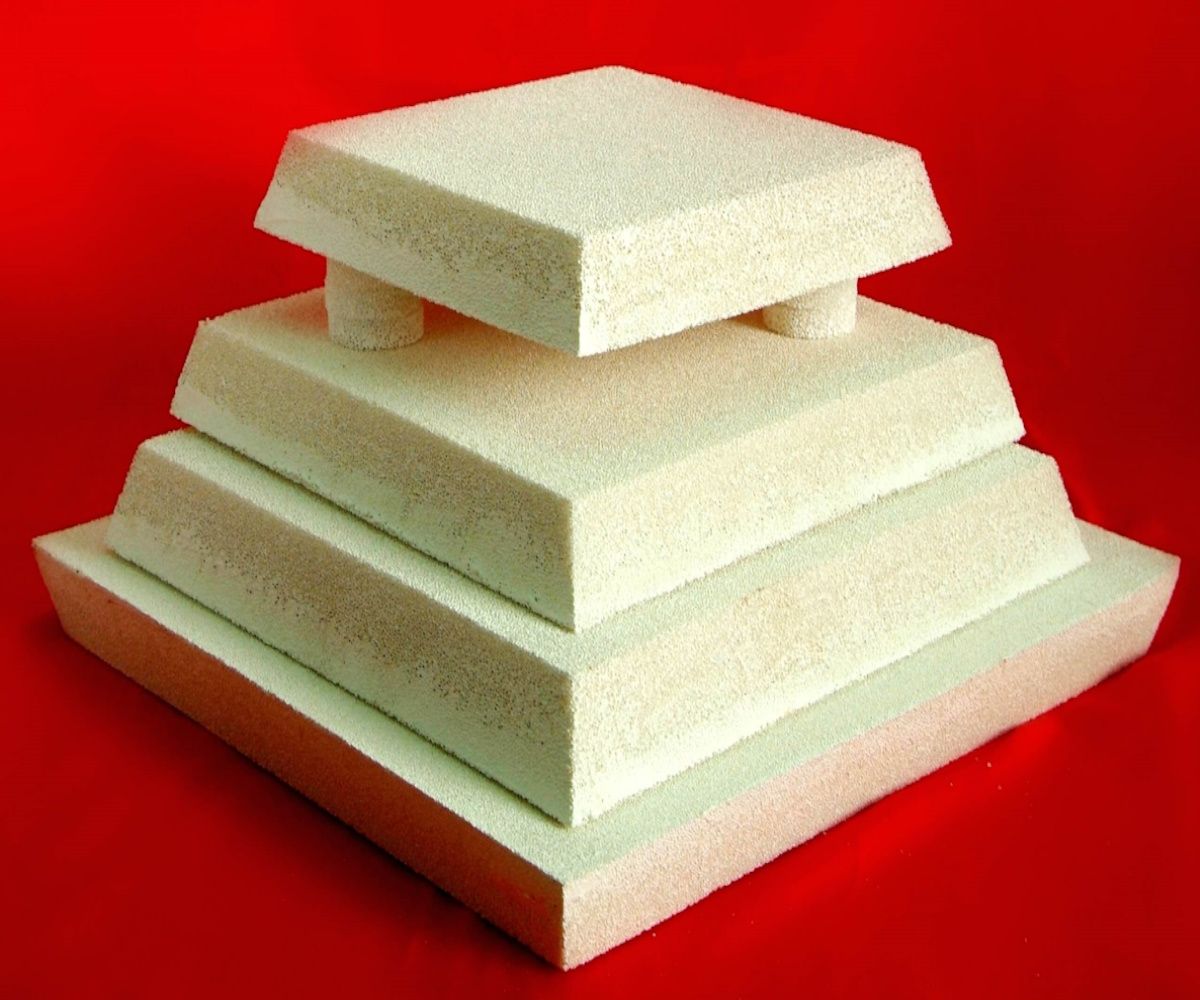

| Packaging Details | DEGASER tablets are available in four sizes 50 gm , 100 gm , 250 gm and 500 gm. DEGASER tablets are wrapped in poly lined aluminium foil and supplied in cardboard boxes. |

| Transportation Details | Road / Ship Transport |

Description

A range of chemical degassing and degassing cum grain refining agents for aluminium and its alloys.

Even under the best melting conditions, it is often impossible to prevent hydrogen gas from entering the melt which finally gives rise to porosity in the cast products. It is therefore necessary to remove as much of hydrogen from the melt as possible prior to pouring. DEGASER range of products removes dissolved hydrogen by diffusion process. Degassing with these products is superior to flushing with chlorine gas which is associated with problems of space, equipment, corrosion, health hazards, etc. Some of the degassing products contain grain refining elements also and these products function as combined degassing and grain refining agents.

Application:

Plunge the recommended quantity as per the application guide to the bottom of the melt using a preheated cylindrical or rectangular basket type plunger when the temperature is falling. The degassing should be continued until the bubbling ceases. Coat the plunger with a refractory coating to prevent iron pick up. Dry the plunger completely before use. Remove the wrapper before the DEGASER tablets are plunged, otherwise metal may pick up hydrogen from the decomposition products of the wrapper. Do not expose DEGASER tablets to atmosphere as far as possible as moisture pick up would result. As a gentle rolling action creates more efficient degassing than a turbulent action, apply DEGASER tablets in two or more successive operations rather than in a single operation. In case of Al-Si Hypoeutectic and eutectic alloys, degas before modification treatment. This helps in securing a constant degree of modification by destroying any existing modification and then remodifying to a known and desired extent. In the case of AI-Si hypereutic alloys, degas before and after grain refining treatment. This helps in knocking off sodium present in the melt before grain refinement and in getting better dispersion of the primary silicon particles after grain refinement.

DEGASER range of products:

Customer Benefits:

Eliminates hydrogen gas porosity, removes non-metallics and enables polished finishes for plating and anodizing. Improves mechanical properties. Are available in tablet form and can be plunged with a simple plunging tool. Are supplied in a wide range of grades and sizes for economical, accurate and efficient metal treatment.

Other Products

Post requirements