Lomag

By: Scottish Chemical Industries| Price | Available on request |

| Category | Consumables |

| Manufacturer | Scottish Chemical Industries |

| Min Order Quantity | 500.00 KG |

| Delivery Lead Time | 7-10 Days |

| Place of Origin | Maharashtra, India |

| Supply Ability | Customization on Requirement |

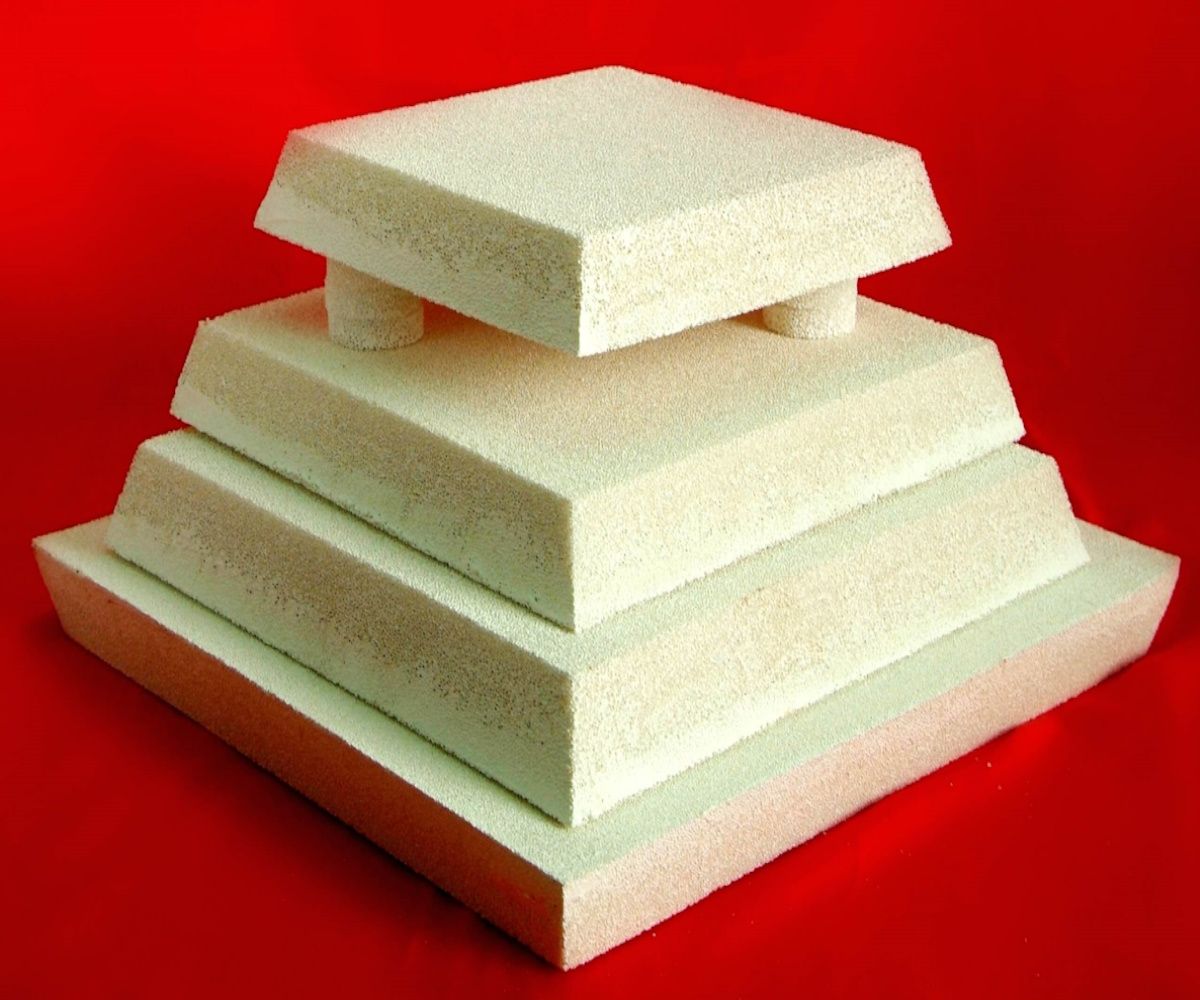

| Packaging Details | Powder is packed in 25 Kg HDPE Lined bags. 2. Smaller packing of 5 Kg is also available on request. 3. Tablets of 50 grm, 100 grms and 500 grms. |

| Transportation Details | Road / Ship Transport |

Description

A white coloured powder / Tablet for removing contaminating amounts of magnesium from molten aluminium and its alloys. As a simple plunging method of removing unwanted minor amounts of magnesium from molten aluminium and aluminium alloy. Fairly high metal temperatures improve the efficiency of the reaction. The method is best used with crucible type melting furnaces.

Specifications

Aluminium alloys contaminated with minor amounts of magnesium can quickly and conveniently be brought within specification without undesirable superheating. The treatment also degasses and a subsequent conventional degassing treatment may not be necessary.

Note: A fair amount of fume is given off during removal of magnesium particularly at high metal temperatures. Adequate extraction/ ventilation should therefore be provided.

Application

LOMAG flux decomposes when heated to 750-800 0 C (1382 – 1472 0 F) to release products which react preferentially with magnesium and remove it from the melt. LOMAG also exerts a degassing and cleansing action thus enhancing its attraction for application to reclaimed materials & dirty charges. How to use : If the initial magnesium content is above 1% add sufficient magnesium- free metal to bring it down to this level. Heat the melt to 750-800 0 C and plunge the packets of LOMAG slowly beneath the surface, holding until the reaction ceases. For most efficient results the total amount of LOMAG should be divided up and the treatment carried out in stages. Use a refractory paint protected and pre-heated cast iron plunger or plunging box furnished with holes to provide a stream of bubbles. Amount to Use : Use 1 kg of LOMAG per 100 kg of metal for every 0.1% approximately of magnesium to be removed.

Other Products

Post requirements