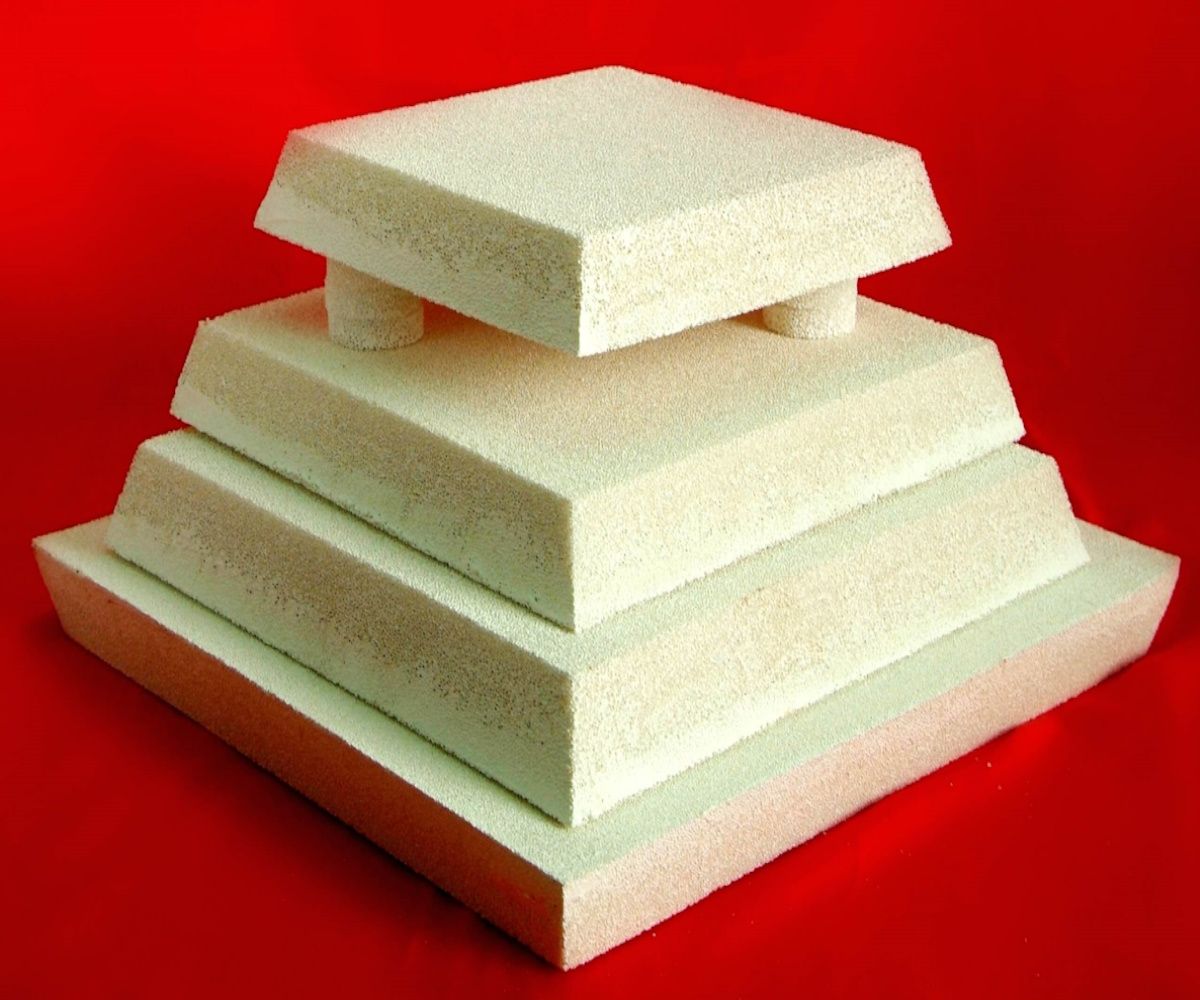

SCOT-GR 2516 - Granulated Fluxes

By: Scottish Chemical Industries| Price | Available on request |

| Category | Consumables |

| Manufacturer | Scottish Chemical Industries |

| Min Order Quantity | 500.00 KG |

| Delivery Lead Time | 7-10 Days |

| Place of Origin | Maharashtra, India |

| Supply Ability | Customization on Requirement |

| Packaging Details | 5 Kg / Bag, 25 Kg / Box, 1 Ton / Pallet |

| Transportation Details | Road / Ship Transport |

Description

COVERAL GR 6511 (E) is a drossing off flux for all those alloys sensitive to any traces of Soduium are undesirable and for most Aluminium alloys melted in either crucible or bale our furnaces. Purpose: COVERAL GR 6511 (E) provides protection for AL Mg alloy melts reducing any contamination from furnace atmosphere. A dry type of slag is formed which coalesees the oxides of Magnesium and Aluminium to enable a clean dross separation. Being a sodium free flux, COVERAL GR 6511 (E) does not transfer any sodium to the melt during reaction thus avoiding the difficulties associated with small amounts of the element in such alloys. Also it forms a protective layer reducing oxidation and further hydrogen pick up. A thorough exothermic cleansing action removes oxides and non-metallic impurities leaving behind a dry dross with particularly low Aluminium content.

Application:

Add sufficient COVERAL GR 6511(E) to form a layer usually at an application rate * of 0.2 to 0.4% of the metal weight. It is preferable to add this quantity in two stages – half at an early stage of melting and half before degassing with MDU (i.e. when charge is in complete molten condition). The cover should be present during early stages of melting and should be maintained as in tact as far as possible. After degassing and grain refining (if carried out with salt based products) a further small quantity of flux should be added and well rabbled into the immediate surface of metal with the existing flux until red glowing dross is obtained. Allow the melt to stand quietly for 2-3 minutes. The powdery dross is to be skimmed off before pouring is started.

Benefits :

COVERAL GR 6511(E) flux is a specially developed exothermic flux in granular form for aluminium alloys being used at relatively lower temperatures and has the following benefits:

- No dust,

- Low fumes

- Reduced particulate emissions

- Eco friendly

- Lower application rate

- Easy to use

Other Products

Post requirements