Industrial Aluminium Profile

By: SHANDONG HUAJIAN ALUMINIUM CO.,LTD| Price | Available on request |

| Category | Industrial Extrusion |

| Manufacturer | Shandong Huajian Aluminium Co.,Ltd |

| Min Order Quantity | 2.00 Tons |

| Delivery Lead Time | As per Order |

| Place of Origin | China |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

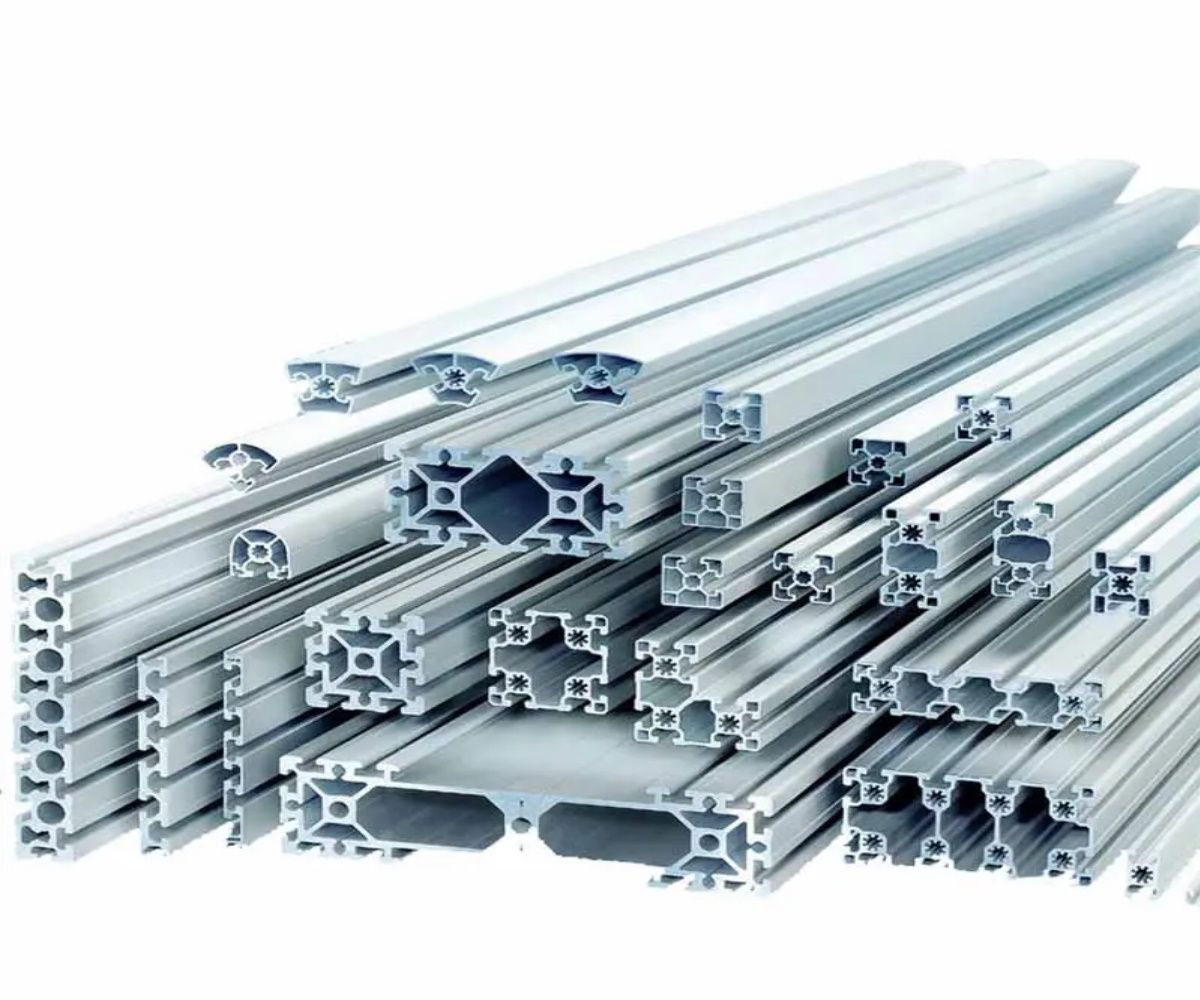

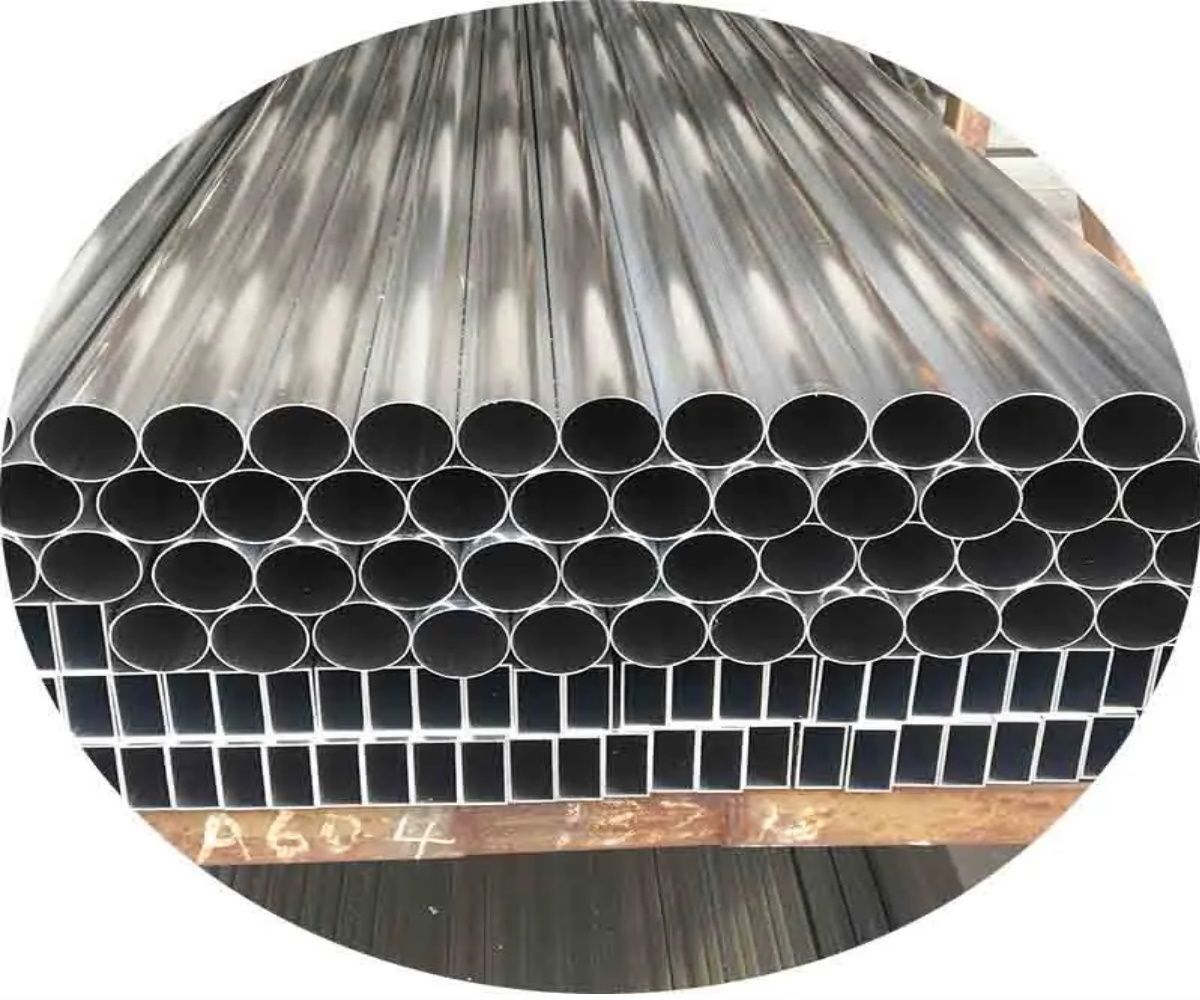

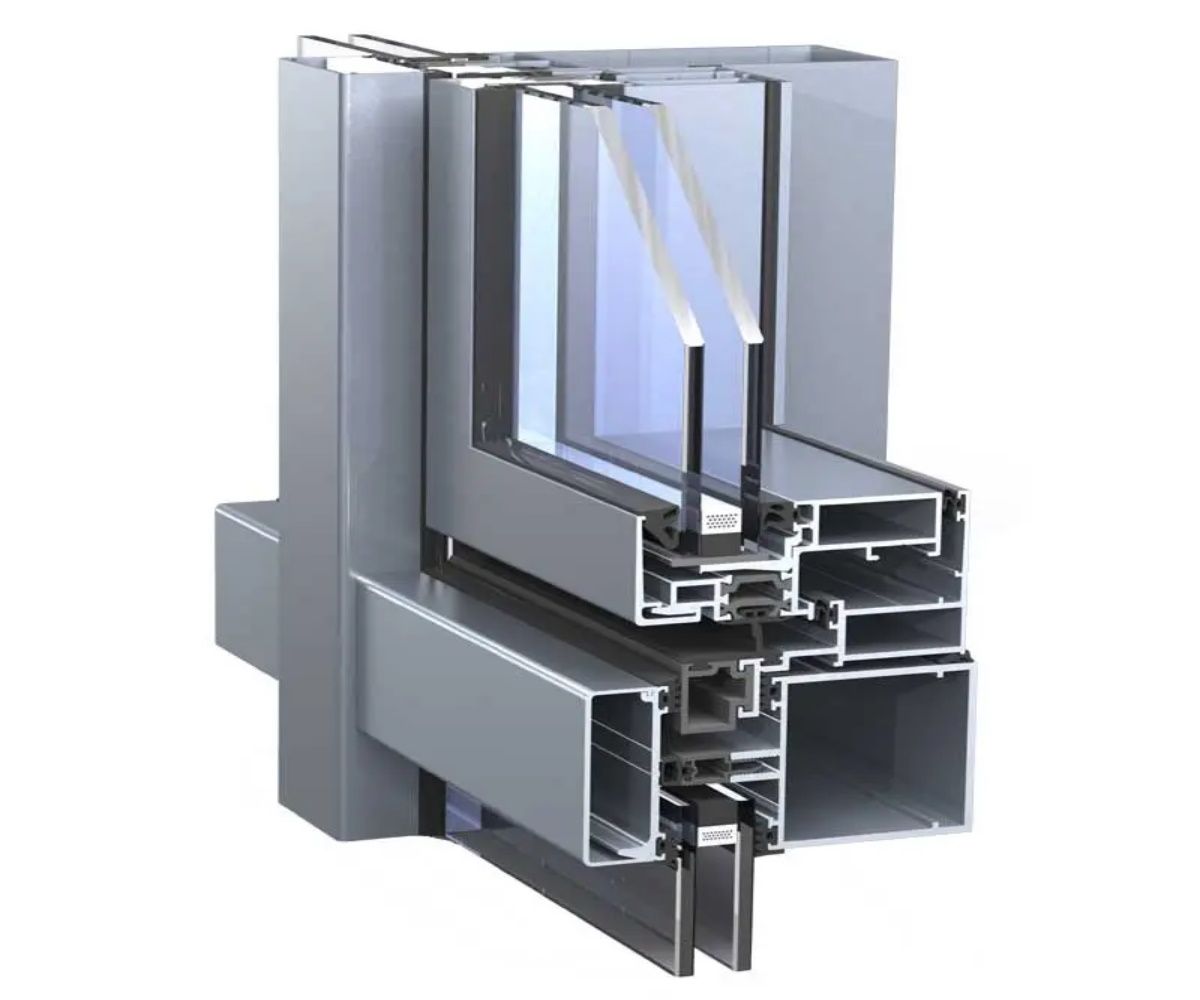

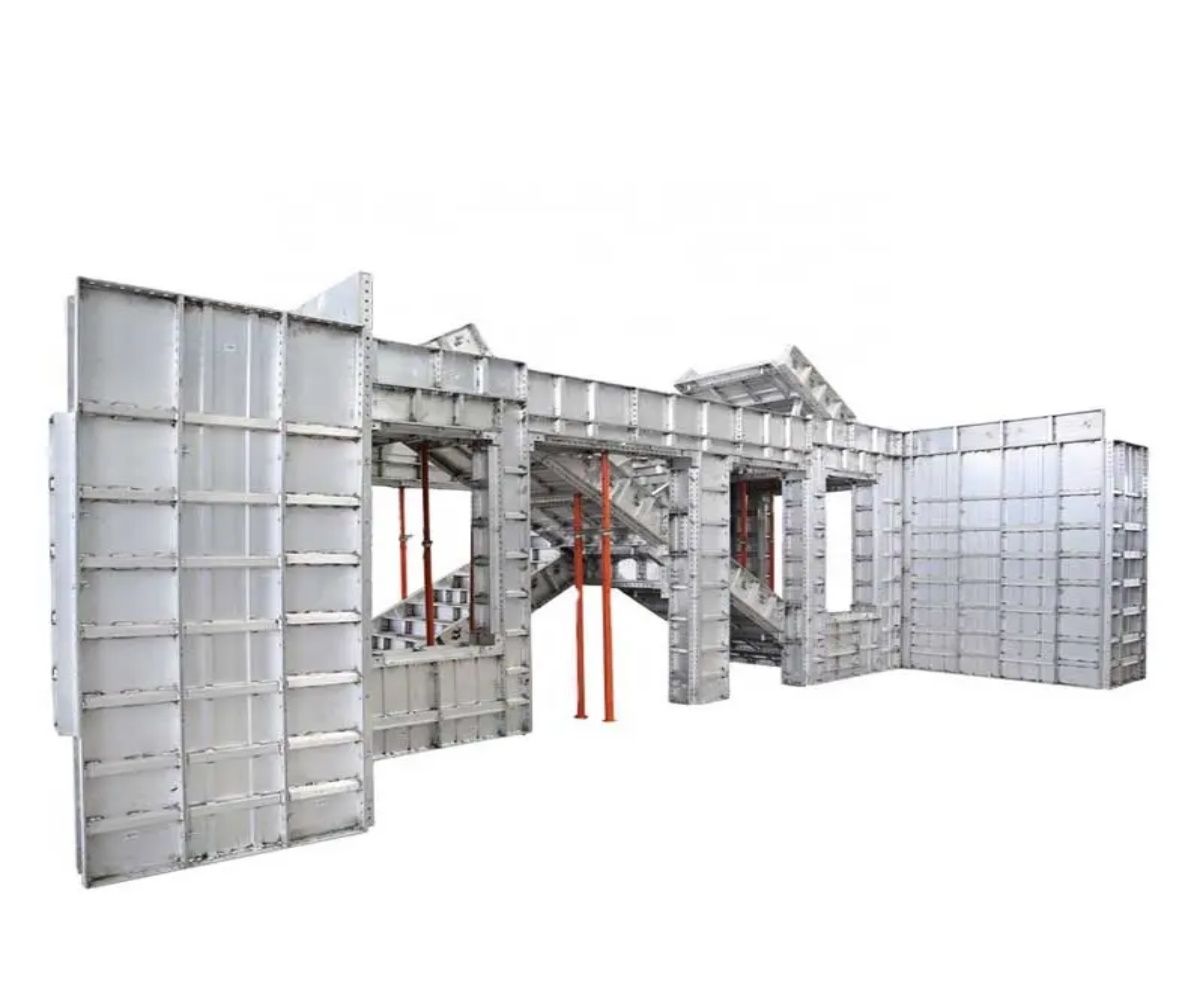

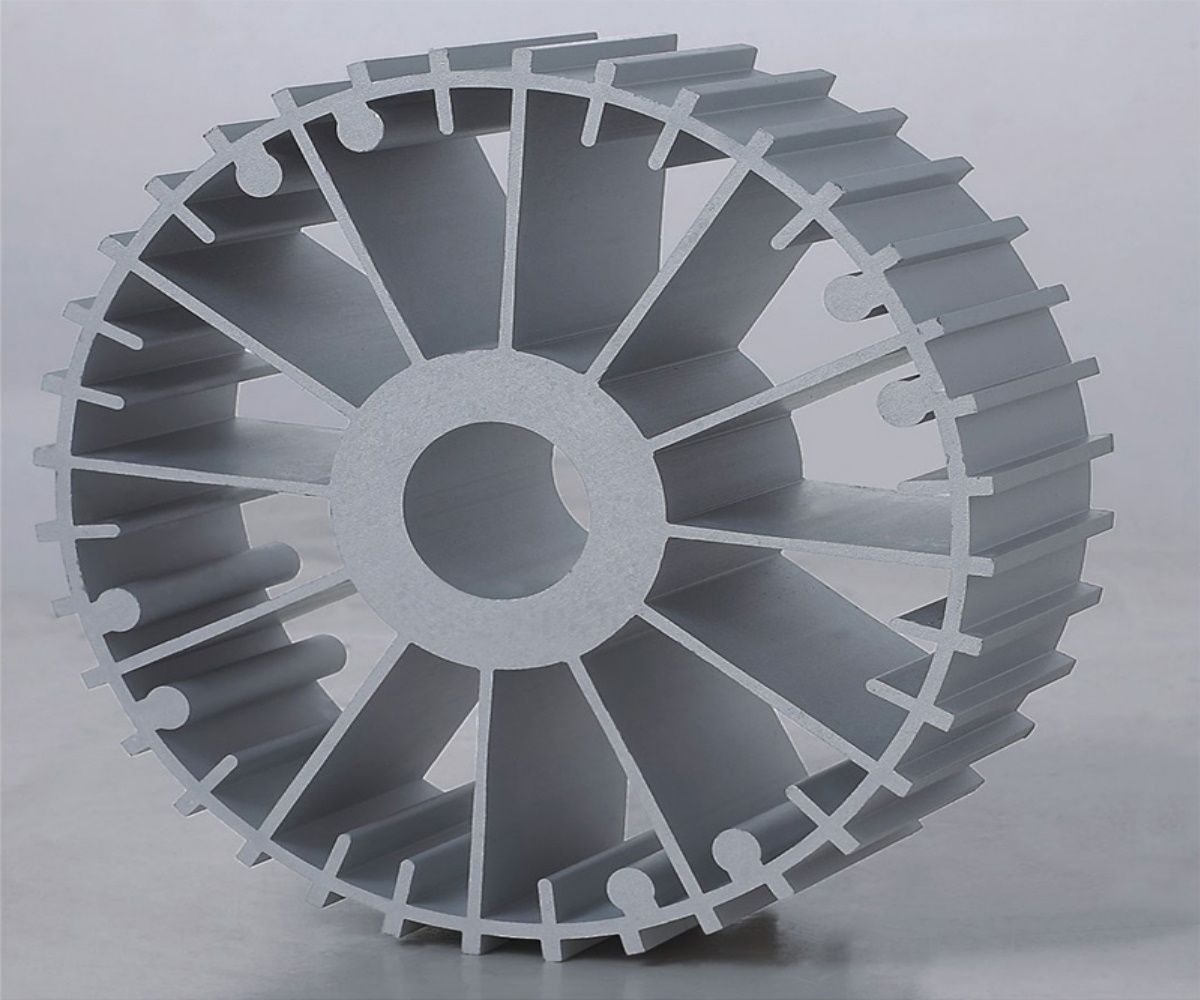

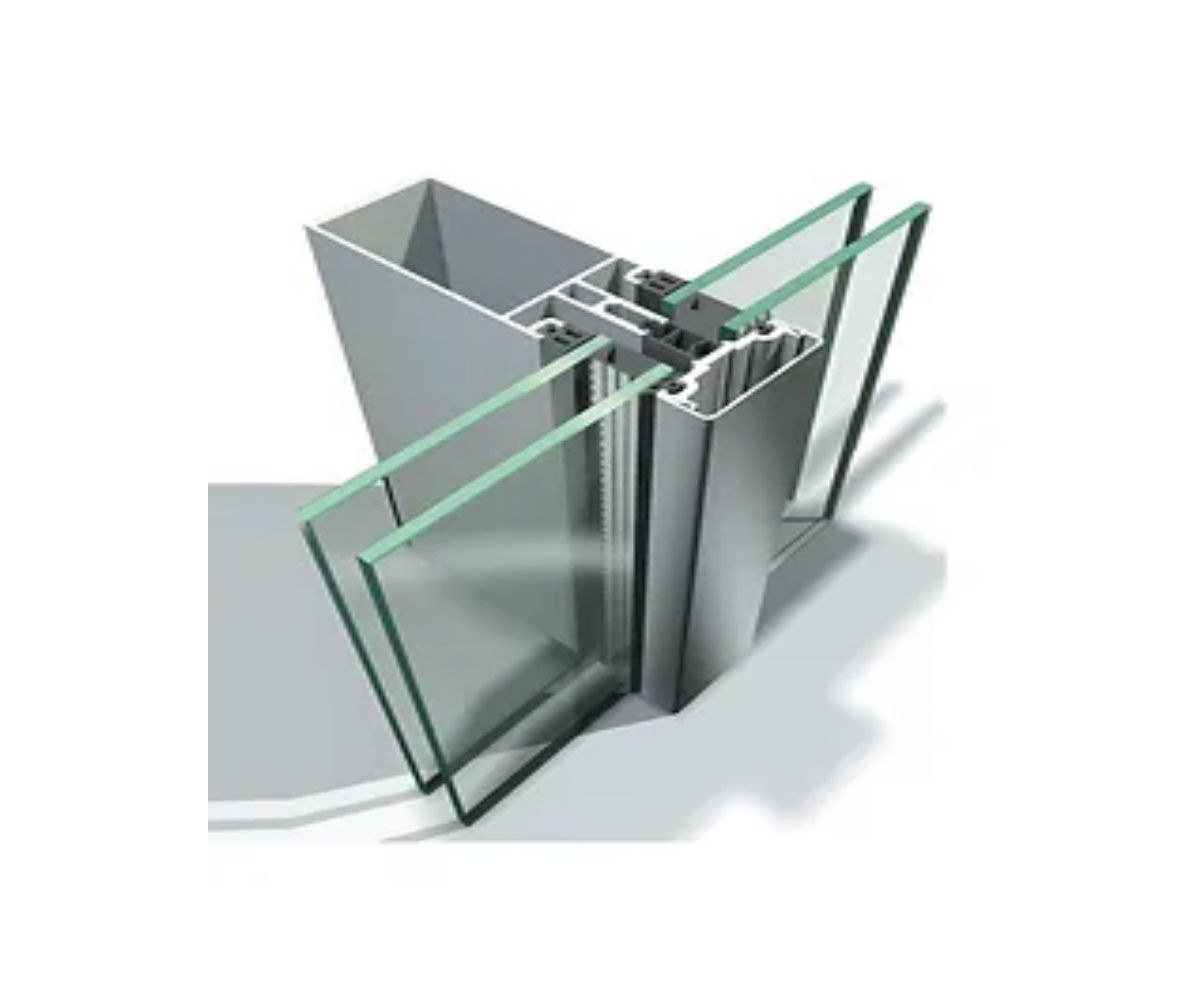

Industrial aluminum profile, also known as: industrial aluminum extrusion material, industrial aluminum alloy profile. Industrial aluminum profile is an alloy material with aluminum as the main component. Aluminum rods can be obtained with different cross-section shapes through hot melting and extrusion. However, the proportion of added alloy is different, so the mechanical properties and application fields of industrial aluminum profiles are also different. Generally speaking, industrial aluminum profiles refer to all aluminum profiles except those for building doors and windows, curtain walls, indoor and outdoor decoration and building structures.

Now Huajian aluminum alloy frames and brackets occupy most of the industry market and replace a lot of steel consumption. Why are aluminum alloy profiles so popular? We would like analyze our aluminium profile’s advantages comparing to steel.

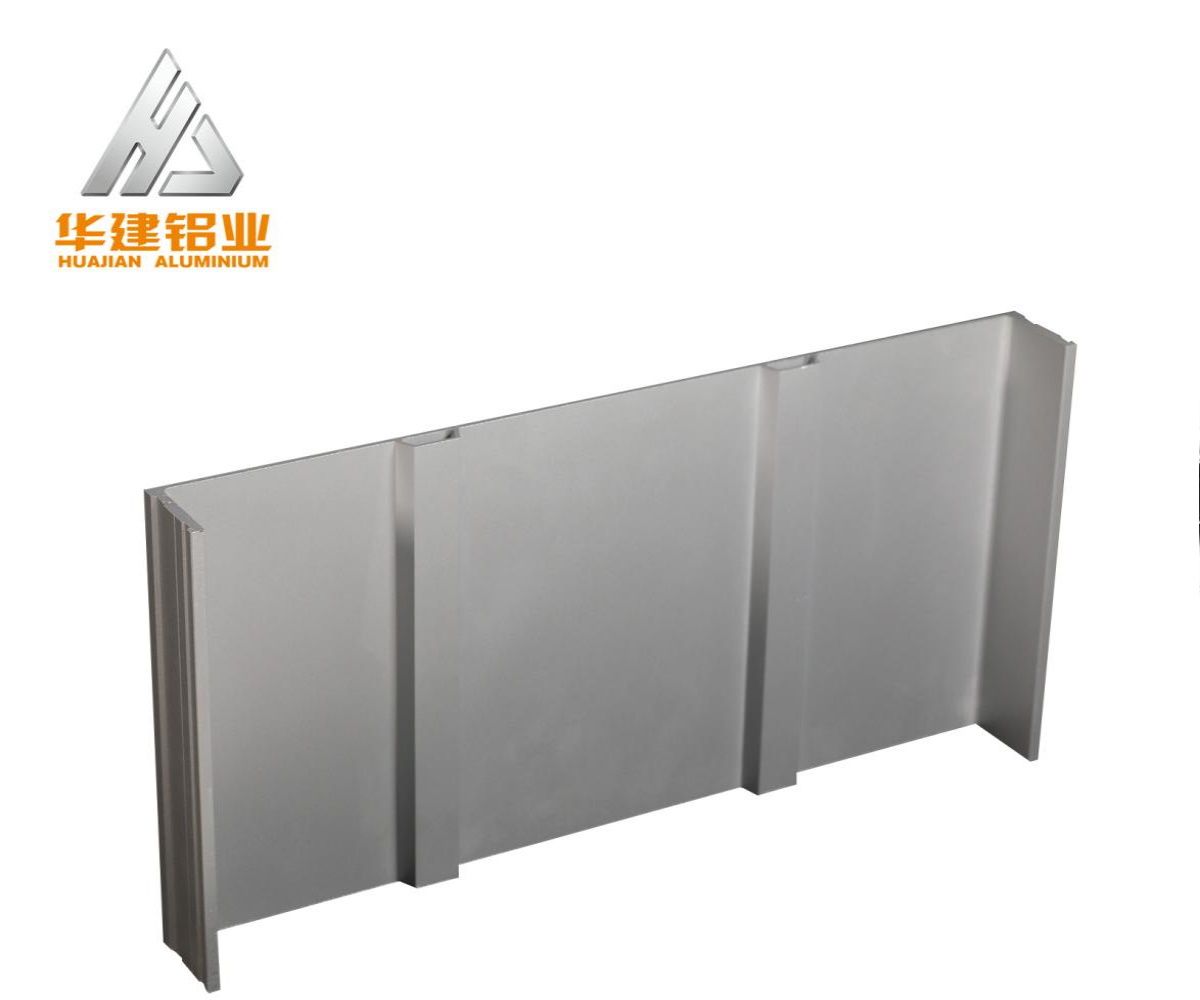

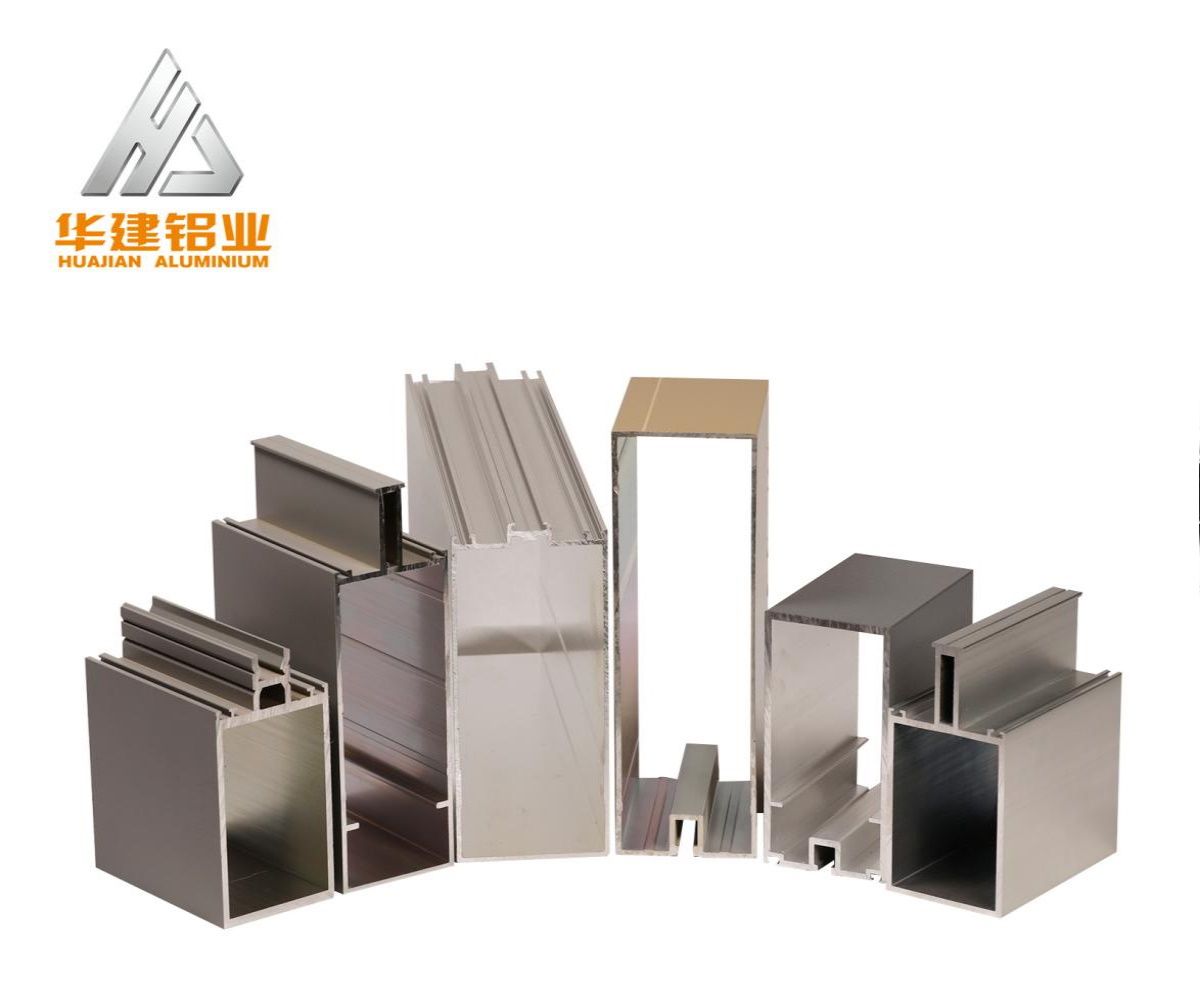

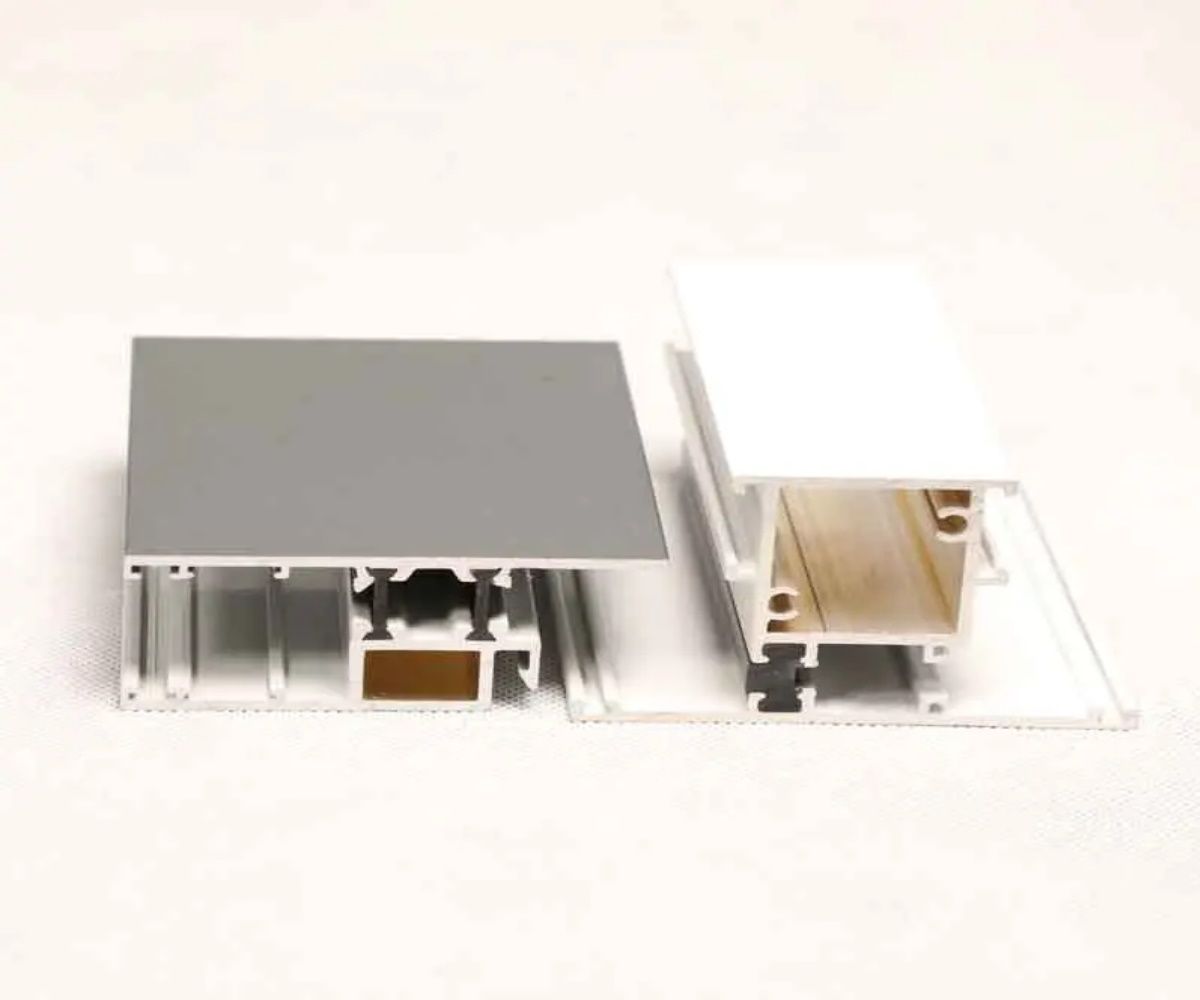

1.Appearance:There are many surface treatment methods for aluminum alloy profiles, such as anodizing, chemical polishing, fluorocarbon spraying, electrophoretic coating, etc. The appearance is beautiful and can adapt to various environments with strong corrosion effects.

Steel generally uses hot-dip galvanizing, surface spraying, paint coating, etc. The appearance is inferior to aluminum alloy profiles. It is also inferior to aluminum profiles in terms of corrosion resistance.

2. Various Cross Section:

The general processing methods of aluminum alloy profiles include extrusion, casting, bending, stamping, etc. Extrusion production is the current mainstream production method. By opening the extrusion die, any cross-sectional profile can be produced, and the production speed is relatively fast .

Steels generally use rolling, casting, bending, stamping and other methods. At present, rolling is the mainstream production method for producing cold-formed steel. The cross section needs to be adjusted by a rolling wheel set, but the general machine can only produce similar products after being shaped. , The size is adjusted, and the cross-sectional shape cannot be changed, such as C-shaped steel, Z-shaped steel and other cross-sections. The rolling production method is relatively fixed and the production speed is relatively fast.

1. Material recycling

The maintenance cost of steel structure increases by 3% every year, and the bracket of aluminum structure hardly needs any maintenance and maintenance, and the aluminum material still has a recovery rate of 65% after 30 years. The price of aluminum is expected to increase by 3% every year. After 30 years, it is basically a pile of scrap iron with no recycling value.

2. Anti-corrosion

At present, the main anti-corrosion method of the bracket is hot-dip galvanized steel 55-80μm, and aluminum alloy is anodized 5-10μm.

Aluminum alloy is in the passivation zone in the atmospheric environment, and a dense oxide film is formed on its surface, which prevents the surface of the active aluminum matrix from contacting the surrounding atmosphere, so it has very good corrosion resistance, and the corrosion rate increases with time. Under normal conditions (C1-C4 environment), the thickness of 80μm galvanized steel can be guaranteed to be used for more than 20 years, but in high-humidity industrial areas or high-salinity seashores or even temperate seawater, the corrosion rate is accelerated. The amount needs to be 100μm, and it needs to be maintained regularly every year.

● Refer attachment for product properties

Other Products

You may be interested in

Post requirements