Automobile Aluminium Profile

By: SHANDONG HUAJIAN ALUMINIUM CO.,LTD| Price | Available on request |

| Category | Automotive Extrusion |

| Manufacturer | Shandong Huajian Aluminium Co.,Ltd |

| Min Order Quantity | 2.00 Tons |

| Delivery Lead Time | As per Order |

| Place of Origin | China |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

Huajian Aluminium group research shows that about 75% of energy consumption is related to the weight of automobile,decrease car‘s weight can effectively reduce fuel consumption and emissions. Compared with steel, aluminum has obvious advantages.

Huajian Aluminium group research shows that about 75% of energy consumption is related to the weight of automobile,decrease car‘s weight can effectively reduce fuel consumption and emissions. Compared with steel, aluminum has obvious advantages. The density of aluminum is only about 1/3 of that of steel. At the same time, aluminum is also the second only to steel in domestic industrial materials. It is very mature in the production and supply industry and has the ability to supply the automotive industry stably, which can meet the requirements of the automotive industry for the quality control system.

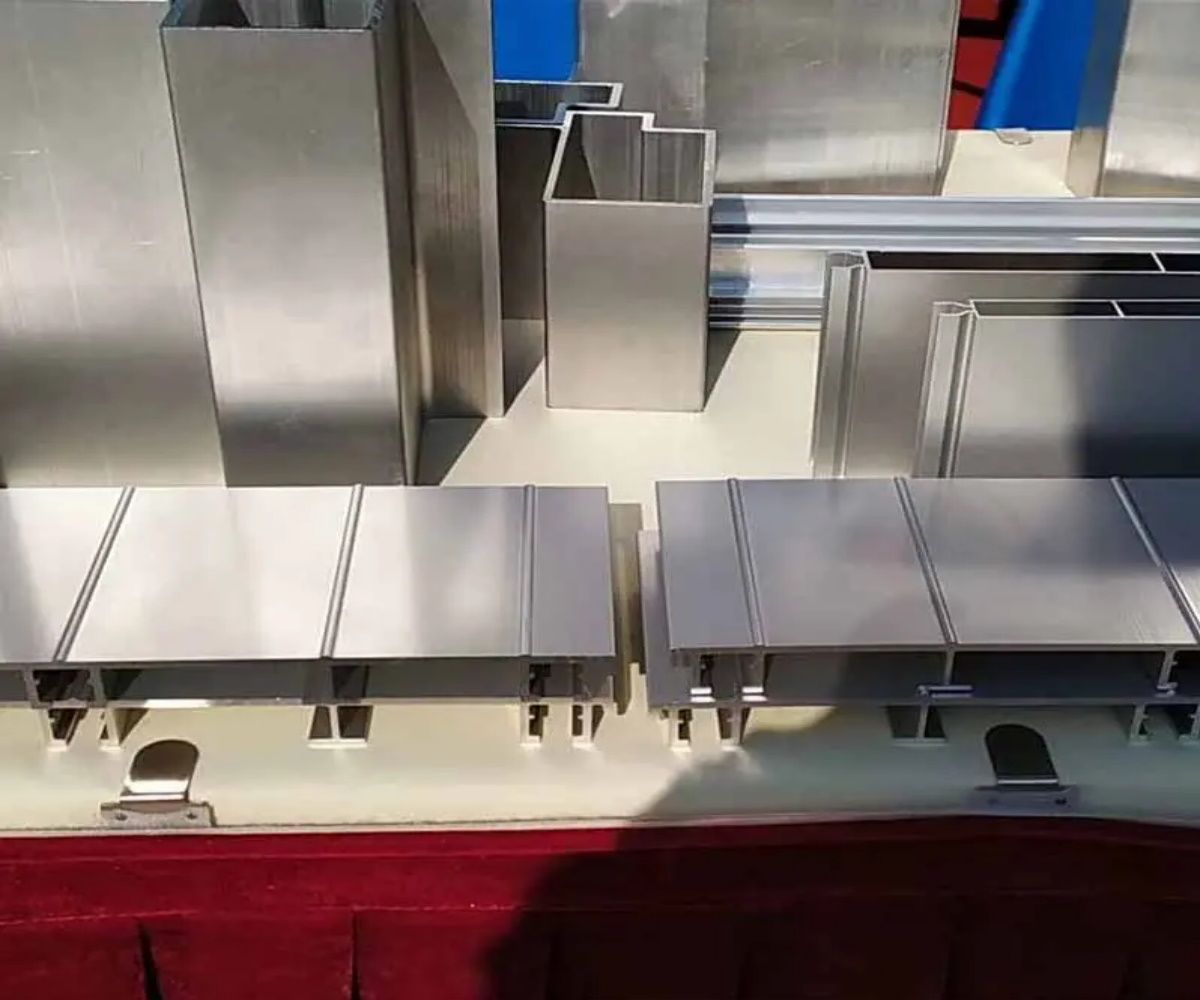

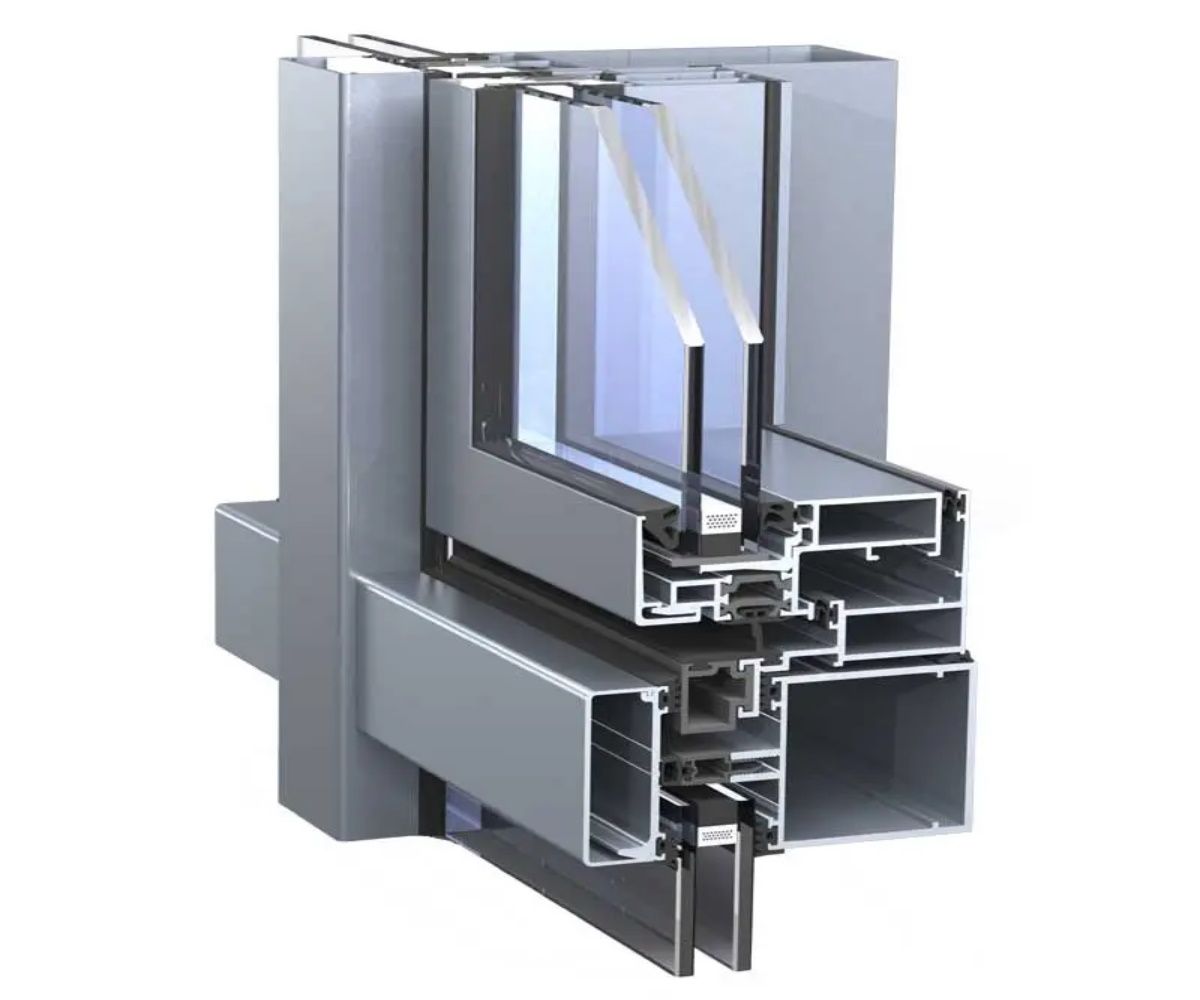

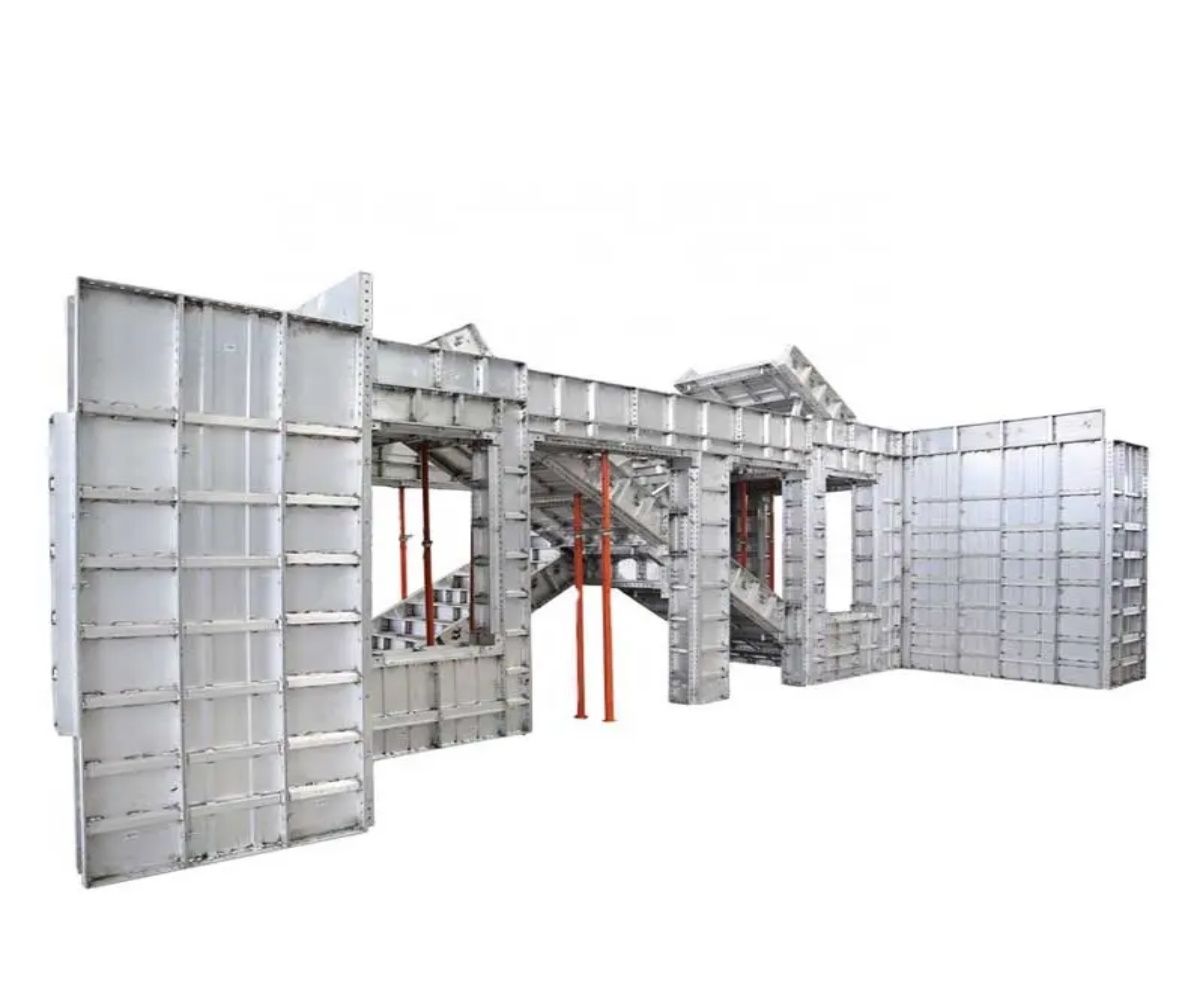

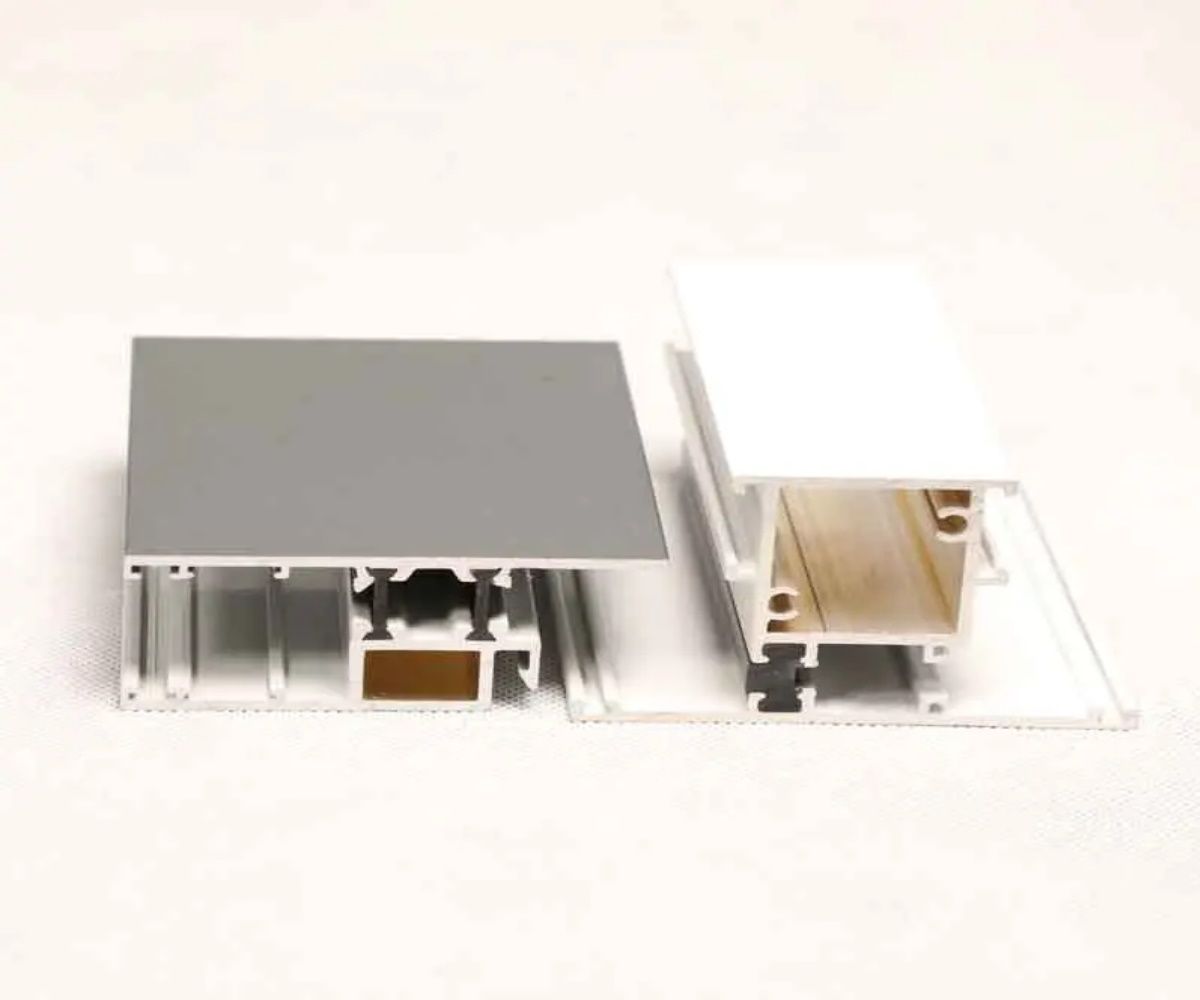

There are three main forming forms of aluminum alloy in car body applications: stamping,extrusion molding, casting molding. Stamping is mainly based on sheet material, through the design of molds, processing and forming, usually requires several sequences to achieve, more suitable for mass production of parts, such as door outer panels, hair cover inner and outer panels and other parts; extrusion forming It is mainly suitable for making some long beam parts. Through the designed cross-section which is more complicated than steel, the overall performance in terms of stiffness and collision, such as longitudinal beams, front and rear anti-collision beams, etc. Some parts that use steel require multiple parts, while using cast aluminum can be achieved with only one part, such as tower supports. The characteristic of aluminum is that its elastic modulus is 1/3 of that of steel. According to theoretical analysis, the rigidity of 1.4 times the thickness of aluminum can be equivalent to that of steel. In theory, from the perspective of ensuring the rigidity of the car body, replacing steel with aluminum with 1.4 times the thickness of steel can achieve the same rigidity and reduce weight by 50%. In the existing models, the inner plate is mainly made of 5 series aluminum alloy, and the outer plate is mainly made of 6 series aluminum alloy with bake hardening characteristics. Cast aluminum and extruded aluminum can achieve further performance through complex cross-section design.

Extruded aluminum alloy is mainly used in some beam parts of the car body.

Such as door sills, longitudinal beams, beams, etc., extruded aluminum can obtain better rigidity and collision through a more complex cross-sectional structure than steel. In the 1990s, Japan built an all-aluminum NSX sports car with an all-aluminum body. Extruded profiles accounted for 12% of the total weight. With the gradual progress of the high-precision three-dimensional bending processing technology of the profiles and the structure control and strength control technology of 6-series alloys Increase the weight of the extruded aluminum alloy used in Honda’s INSIGHT to 30%. However, with the development of other technologies and the impact of the market environment, the weight of extruded profiles in the ECB car body in the past 10 years is about 3%, and the range of parts used is relatively stable.

The low density of aluminum alloy makes it an important material for lightweight body.

In terms of substituting steel, the performance of the whole vehicle can be improved through the thickness of about 1.5 times and the special structural design of the casting; in terms of the weight ratio of the bicycle, the proportion of sheet metal stamped aluminum is the largest, followed by cast aluminum and extruded aluminum. However, in the side panel assembly that needs to absorb energy efficiently and reduce the amount of intrusion, it has no advantages compared with hot formed steel.

Huajian Aluminium group has been make effort on extrusion aluminium material since 2000, and the company production skill is matured on automobile supply.

Other Products

Post requirements