Aluminium wire rod: Transforming the power transmission and distribution sector landscape

Team AL Circle

2023-11-11

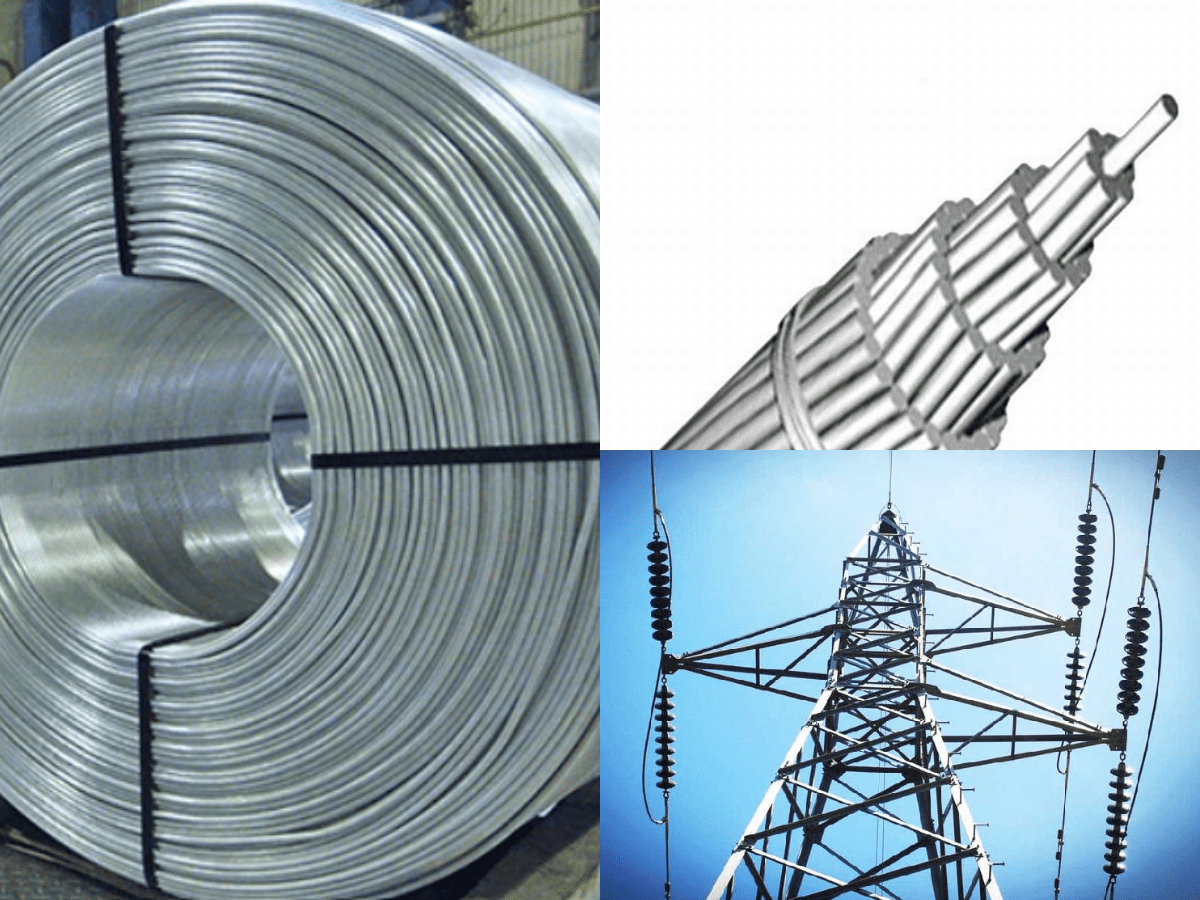

As a lightweight and versatile material, aluminium has found widespread use in various applications. From the latest gadgets to building materials, aluminium is seen everywhere today. Even the power transmission and distribution sector that once relied heavily on copper is shifting or, to some extent, switched towards aluminium for a number of reasons. As the sector strives to meet the demands for efficiency and environmental sustainability, aluminium wire rods emerge as a clandestine force reshaping its landscape.

These long, cylindrical-shaped bars are produced using the technique of rolling or extrusion. They are used as raw materials for producing various aluminium products like wires, cables, electrical conductors, and components of transformers. Their conductivity, lightweight nature, and eco- friendly attributes position them as pivotal components in the ongoing transformation of the power industry. It is estimated that the market size of these wire rods will reach USD 69.09 billion by 2027. Let us now discuss the profound impact of aluminium wire rods and how it has already opened a world of opportunities in the power and transmission industry.

What makes aluminium wire rods superior to other metals in the electrical sector?

To begin with, aluminium wire rods have a larger cross-section than their copper or steel counterparts. Besides, there are a host of other physical properties that make aluminium the ideal choice for wire makers in the electrical industry. These properties are:

• Lightweight: The weight of the aluminium is around 2.71 g/cm3, which is approximately one-third of the weight of the steel (7.85 g/cm3). Even copper weighs 8.96 g/cm3 more than aluminium. This property of aluminium makes it more appropriate for use in overhead transmission wires and easier to transport than other metals.

• Corrosion resistance: Aluminium does not rust, but it may corrode. However, the aluminium oxide coating formed on the aluminium wire rod's surface when exposed to air makes it almost corrosion-resistant.

• High conductivity: Just like copper, aluminium is also a good conductor of electricity. The aluminium wires have a much larger cross-sectional area than copper, offering the same current carrying capacity while remaining lighter.

• Eco-friendly nature: Aluminium wire rods are non-toxic and easy to recycle. In fact, aluminium can be recycled endlessly without having to lose its conductivity. This makes it a much eco-friendlier option than other metals like copper and steel.

• Excellent tensile strength: The tensile strength of the aluminium is around 90 MPa, which means it can endure maximum stress without being stretched or pulled.

Applications of aluminium wire rods in the power transmission and distribution sector

1. Overhead transmission lines: Aluminium wire rods are strong yet flexible. So, they are ideal for making overhead transmission lines.

2. Fasteners: Aluminium is also being used to manufacture fasteners such as nuts, bolts and screws due to its good mechanical properties.

3. Transformers: The weight of aluminium is significantly lighter than copper. So, it makes a better choice for manufacturing windings in transformers. These transformers are used to increase or decrease the voltage of electricity.

4. Underground Cables: Aluminium wire rods are used for making underground cables in urban infrastructural setups.

Reasons for shifting towards aluminium

Earlier, metals like steel, copper and nickel were used heavily in the power and transmission industry for making wires. However, with the changing focus towards environmental sustainability and lesser energy consumption, every sector, including power and transmission, is shifting towards aluminium, which is endowed with all the qualities of a great conductor - plus, it is 100% recyclable.

Aluminum is favoured for high-tension power lines due to its superior conductivity by weight, cost-effectiveness, and reduced weight considerations. While copper boasts better conductivity by volume and cross-section, the advantageous combination of lighter weight and lower cost makes aluminium the preferred choice for main overhead power lines transmitting electricity over long distances. In practical terms, an aluminium wire with a 1.5 times larger cross-section is capable of carrying the same current as a copper wire, yet it is two times lighter. This emphasis on weight is a critical factor in designing and implementing high-voltage transmission systems.

The demand for aluminium wire rods has been increasing consistently over the years as they offer a better return on investment. Ducab Aluminium Company (DAC), a joint venture of two organisations, produces aluminium or aluminium wire rods and many other products. They employed eco-friendly processes within their mill for the production of aluminium.

Vedanta Aluminium has also launched its own set of wire rods, such as T4, AL59 and the 8xxx series, which offer numerous benefits. They are specifically designed to deliver exceptional performance in the power and transmission industry.

Conclusion

The aluminium wire rod market plays a pivotal role in the global metallurgical industry, serving as a fundamental component in producing various aluminium products. Aluminium wire rods are essential for manufacturing electrical conductors, cables, and a wide range of industrial applications. The market's dynamics are influenced by factors such as growing demand for lightweight and durable materials in sectors like automotive and construction. Additionally, technological advancements and increasing emphasis on sustainable practices have spurred innovations in aluminium production processes, impacting the wire rod market. As economies continue to develop and infrastructure projects expand, the demand for aluminium wire rods is expected to rise, presenting both challenges and opportunities for stakeholders in the aluminium industry. Economic and environmental considerations and evolving consumer preferences will likely shape the trajectory of the aluminium wire rod market in the coming years.

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us