Green Aluminium – When Will It Become a Reality?

Contributed by: Anonymous

2021-05-19

Most metal producing companies face the dual challenge of energy transition – the need for reducing emission while meeting the global demand for critical commodities. The risk is most significant in case of Aluminium, making it even more difficult to achieve carbon neutral or low carbon aluminium or simply "green aluminium".

Light and durable: aluminium is a wonder material that has revolutionised industries from construction and transportation to packaging and cooking utensils. But aluminium’s most attractive feature may be its impressive recyclability — around 75% of all the aluminium ever produced is still in use today. This is a record unmatched by most materials, and a key reason why the material is likely to play an important role within the transition to a more circular economy.

|

Among metals, aluminium produces the second-highest absolute emissions (2% of the global total – second only to steel) and competes with nickel for highest intensity. It stands to be the metal most affected by carbon pricing as a result.

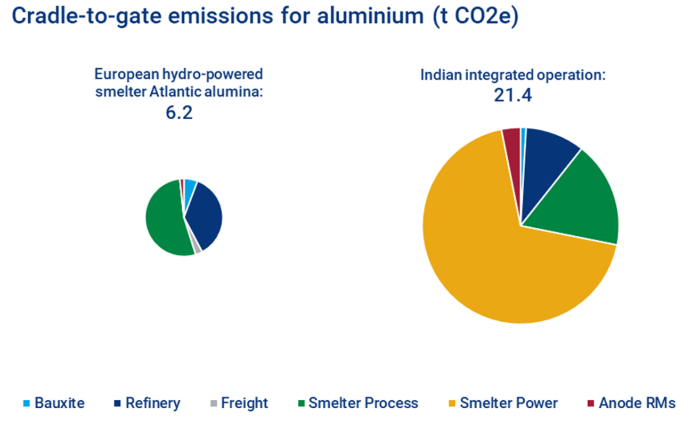

A study by Wood Mackenzie highlights that the typical cradle-to-gate C02 equivalent emissions range from 5-25 tonnes per tonne of metal produced. The study showcases that although raw material sourcing plays a considerable part in emissions the most significant contributor to higher emissions comes from the energy source (smelter power) used. |

Some of the necessary steps needed to be undertaken to achieve low carbon footprint in aluminium production are outlined below:

- The aluminium industry must invest in up-scaling carbon anode replacement technology to reduce emissions from electrolytic cells.

- One of the techniques is replacing the carbon anodes in the electrolytic process by a ceramic material. Only oxygen is emitted. This reduces direct carbon emissions to nearly zero, if used in combination with carbon neutral electricity.

- Increased recycling will also be key, as production of aluminium from scrap takes only 5% of the energy required to smelt alumina. However, not all applications can use scrap as feed, and there simply isn’t enough metal in circulation to meet global demand.

- Localized Supply chain is also expected to reduce freight emissions and contribute to greener aluminium.

- Migrating smelting to locations with renewable energy sources may be necessary in the long term. Currently, coal occupies the majority share as the power source for aluminium smelting.

- Policies that penalise metals produced from high-carbon sources will be necessary to spark real change in the long term. Carbon pricing needs to be implemented more stringently. Till Aug 2020, of the 189 signatories to the Paris Agreement only 58 jurisdictions have implemented such a regime

As the world strives towards the 2030 deadline of for the Sustainable Development Goals of the United Nations, aluminium with its unique virtue of being a 100 % recyclable metal without any quality degradation, presents itself as a much sought-after ingredient in a low-carbon economy. However, the concept of carbon neutral aluminium can be achieved only though stringer implementation of green policies, focussed R&D bringing technological advancement in generating low carbon emissions from aluminium smelting processes and developing localized supply chains.

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us