Innovations in aluminium extrusion: Meeting modern industry demands

Team AL Circle

2024-04-05

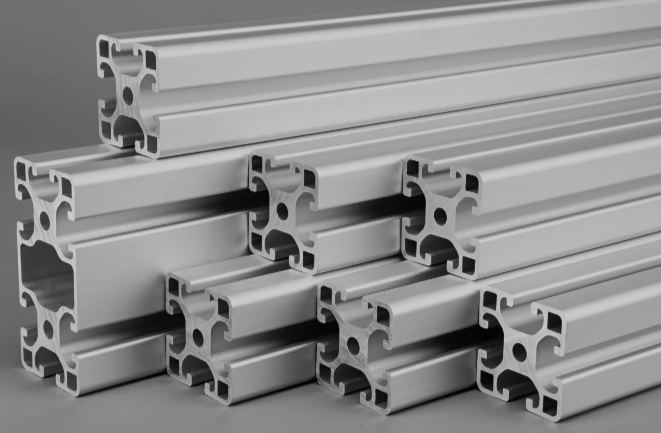

Aluminium is known as a versatile and infinitely recyclable metal, currently one of the manufacturers' favourite materials. Aluminium extrusion is a process of turning aluminium alloy into functional shapes and designs with cross-sectional profiles. The alloy is forced through a specific die to obtain a particular shape.

Aluminium extrusion has been around for several years and is one of the frontline techniques in material engineering. In the post-pandemic era, the aluminium extrusion market rebounded in almost all regions, with global extrusion usage reaching an estimated 31.5 million tonnes in 2023. Over the forthcoming seven years, the aluminium extrusion demand is anticipated to experience a CAGR of approximately 3.51%, reaching a volume of 40.1 million tonnes by 2030. The need for lightweight, design flexibility, innovation and sustainability will drive the demand for aluminium extrusion in the forecasted period. As times have progressed and technology has evolved, aluminium extrusion has most likely entered its golden era.

Five innovations that are modernising the aluminium extrusion industry:

Technology is becoming integral to manufacturing and designing, propelling several industries towards a prospective future. As tech advances in the aluminium extrusion sector, newer possibilities for engineers, technicians and designers will unlock. Here is a list of five innovative technologies and their benefits paving a new path for aluminium extrusion.

1. Artificial intelligence helps in optimisation

2. 3D printing unlocks new design potentials

Aluminium is commonly used for birthing complex designs. 3D printing has the potential to create complex dies which cannot be made with conventional methods. 3D printing is rapidly gaining popularity in multiple industries because of its affordability and ability to create complex designs. The aluminium extrusion industry is no different.

3. Nanostructuring adds a layer of protection

Aluminium is usually known for lending durability and strength to products. Nanostructuring or nano-coating takes it up a notch. This innovative technology is particularly used in the automobile or aerospace industry to achieve an adequate strength-to-weight ratio. An extra-thin layer of protection ensures stability and guards against abrasions and corrosion.

4. Robotics facilitates automation

One of the fundamental changes across all sectors is the rising demand for automation. Robotics is facilitating automation in the aluminium extrusion sector. It significantly minimises the chances of human error and helps manufacturers save money. Like artificial intelligence, robotics helps with product inspection, quality control and waste reduction. All in all, robotics is essential for enhancing productivity and lowering lead time.

5. Recycle engineering ensures sustainability

Similar to aluminium, its alloys also have recycling abilities. New technologies like microwave energy are helping manufacturers accurately segregate aluminium scrap. Sorting aluminium alloy scrap manually can be a tedious job. Modern recycling technology introduces efficiency and accuracy, making the aluminium extrusion process more sustainable.

Innovations in aluminium alloy to facilitate extrusion:

Speaking of innovation, people usually think of technology. However, ALBA (Aluminium Bahrain BSC) developed a new aluminium alloy for aluminium extrusion. Aluminium alloy 6600 HE began in January 2022, and its commercial production commenced ten months later, in October 2022. Three prominent entities from Bahrain-BALEXCO, ALBA and the University of Bahrain joined forces to create this new alloy. 6600 HE aluminium alloy billets aim to improve process and production efficiency. It will also increase the speed of extrusion without compromising the quality of the product.

Technology and aluminium: Two forces that are shaping the future of industries

Manufacturers are finding new and innovative ways to use aluminium in production. Several industries, like automobiles, aerospace, construction, electronics, packaging, etc., extensively use aluminium due to its lightweight, complex structure design and endless recyclability. When these characteristics of the metal are paired with new-age technology, new avenues for several industries are opened. Aluminium extrusion is a vital process in industrial manufacturing. Technologies like AI, robotics and 3D printing are set out to revolutionise the aluminium extrusion and manufacturing landscape forever.

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us