Die Casting Automation on a Budget: Benefits and Challenges

admin

2025-03-03

Automation has transformed manufacturing across industries, and aluminium casting is no exception. While new automated systems are expensive, used die-casting machines with automation capabilities offer an affordable alternative without compromising quality.

However, despite its advantages, automation in aluminium casting comes with its own challenges. This blog explores both the benefits and challenges of automation in aluminium die-casting, focusing on cost-effective solutions like used aluminium die-casting cells.

Benefits of Integrating Automation in Aluminium Casting

1. Cost Savings on Labor and Operations

Automated die-casting cells minimise the need for extensive manual intervention, reducing workforce expenses and lowering the risk of errors that lead to rework or scrap material.

Most used die-casting cells come with automated robotic handling and trimming systems, which reduce the number of operators required, leading to lower long-term labour costs.

2. Reduced Material Waste

Automated die-casting systems ensure precise metal pouring and trimming, reducing excess aluminium waste. This directly lowers production costs.

3. Energy Efficiency and Cost Control

Instead of investing in a new high-tech machine, manufacturers can cut energy costs using a well-maintained, pre-owned model with efficient cooling and melting systems.

For instance, the IDRA Aluminium Die Casting Cell includes an efficient cooling system that reduces energy use and keeps power bills in check.

Challenges of Integrating Automation in Aluminium Casting

While automation presents numerous cost-saving benefits, manufacturers must also be prepared for certain challenges:

1. Initial Investment in Automation

Even when purchasing used automated die-casting machines, businesses still need to budget for installation, setup and employee training. However, compared to buying a brand-new casting system, investing in a pre-owned automated machine offers a more affordable path to automation.

2. Need for Skilled Technicians

Automated aluminium casting systems require trained personnel for programming, troubleshooting and routine maintenance. Some manufacturers hesitate to integrate automation due to concerns about training costs.

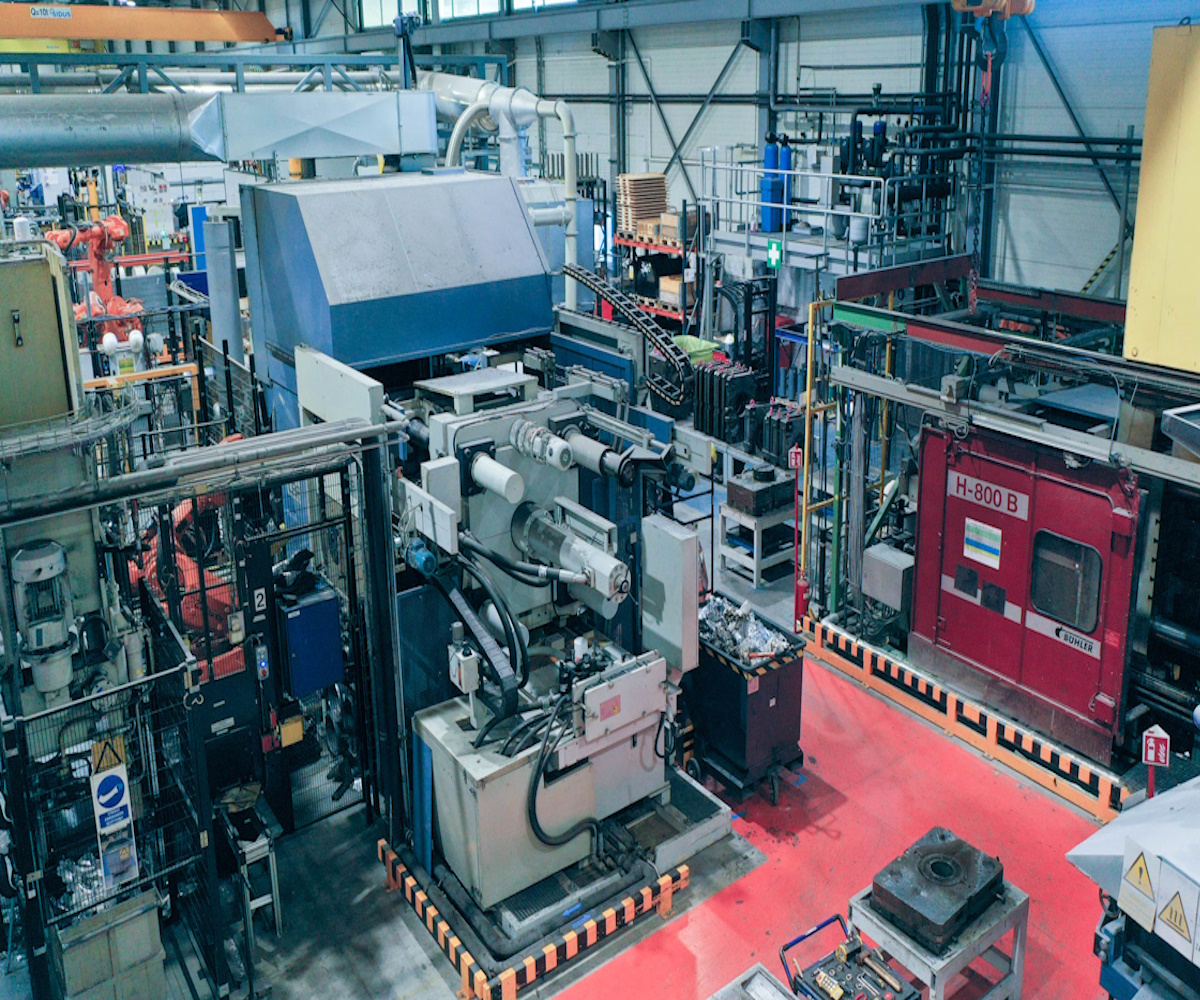

However, older used models like the BÜHLER Aluminium Die Casting Cell have simpler yet reliable automation technology, which means:

- Less complex training is required

- Lower dependency on expensive automation specialists

3. Compatibility with Existing Production Lines

Integrating automated die-casting cells into an existing production setup can be challenging, especially if older manual systems are in place. However, choosing versatile, used models that align with current operations can simplify the transition.

For example, both the IDRA and BÜHLER aluminium die-casting cells come with modular automation features, allowing businesses to incorporate them without completely overhauling their existing systems.

Final Thoughts

Automation in aluminium casting is a game-changer, but new automated machines come with high costs. The smart, cost-effective solution? Investing in used die-casting cells that provide automation benefits with proven reliability and process guarantees.

At AL Biz, we offer pre-owned aluminium die-casting machines that are performance-tested and come with process guarantees where available, ensuring you get quality and efficiency at a fraction of the cost.

If you're considering affordable automation in aluminium casting, explore the options available on AL Biz:

Take the smart route to automation today!

Categories

Raw Materials

Scrap

Consumables

Primary Aluminium

Secondary Aluminium

Equipment

Technology

Downstream Products

Finished Products

Utilities

Services

Others

Recent Blogs

Subscribe to newsletter

Connect with us