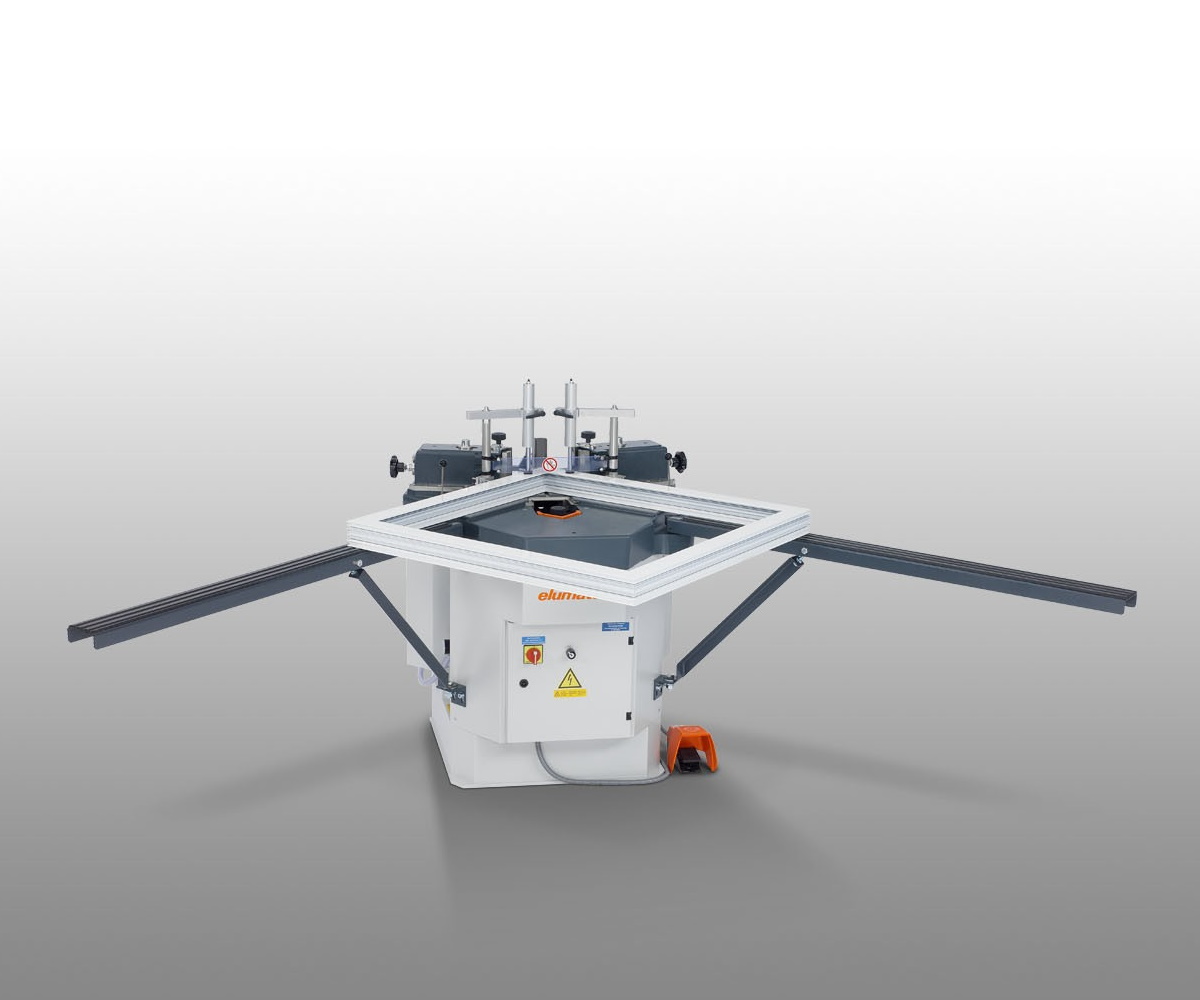

Double Mitre Saw DG 104

By: Elumatec India Pvt Ltd| Price | Available on request |

| Category | Equipment |

| Manufacturer | Elumatec India Pvt Ltd |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per Order |

| Place of Origin | Germany |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

Specification -

- The optimal double mitre saw for series production as well as for special applications

- The universal pivoting and tilting of both saw units allows cutting of high and wide profiles as well as every type of compound mitre. Consequently, many profiles can be cut without support blocks

- External-dimension cuts possible for all cutting variants. Consequently, no complicated length calculations are necessary. This is a big advantage when cutting special angles

- Pivoting range with digital angle display

- Safety hoods

- Equipped with saw blades as standard

- Available with E390 or E590 control system

- Pulsed coolant system

Cutting length variants -

- 3,000 mm

- 4,500 mm

- 6,000 mm

Options -

- DG 104 M machine bed made of steel sheet

(cutting length 4,500 mm, 6,000 mm) - Profile lifting bars

- Software for E 590: Software module for chop and oversize length cuts

- Mobile or automatically retractable workpiece supports

- Material clamping units

- Transom stop and lead-cut stop

- Label printer for variants with E 390 and E 590

- Exhaust connectors, extraction system

- Clock system

- Roller conveyors

- Saw blades

- High-performance cutting fluid

Controller variants -

- Positioning control E 390

- PC Control E 590

Technical Data -

- Minimum cutting length at 90° 350 mm

- Minimum cutting length tilted at 45° 350 mm

- Pivoting range inwards 90° - 45°

(up to 22.5° manual with digital display) - Tilting range inwards pneumatically 90° - 45°

- For cutting range, see cutting diagram

- Saw blade diameter 420 mm

- Saw blade speed 2,800 rpm

- Power supply 230/400 V, 3~, 50 Hz

- Power output per motor 4 kW

- Compressed air supply 7 bar

- Air consumption per working cycle 40 l without spraying, 64 l with spraying

Other Products

Post requirements