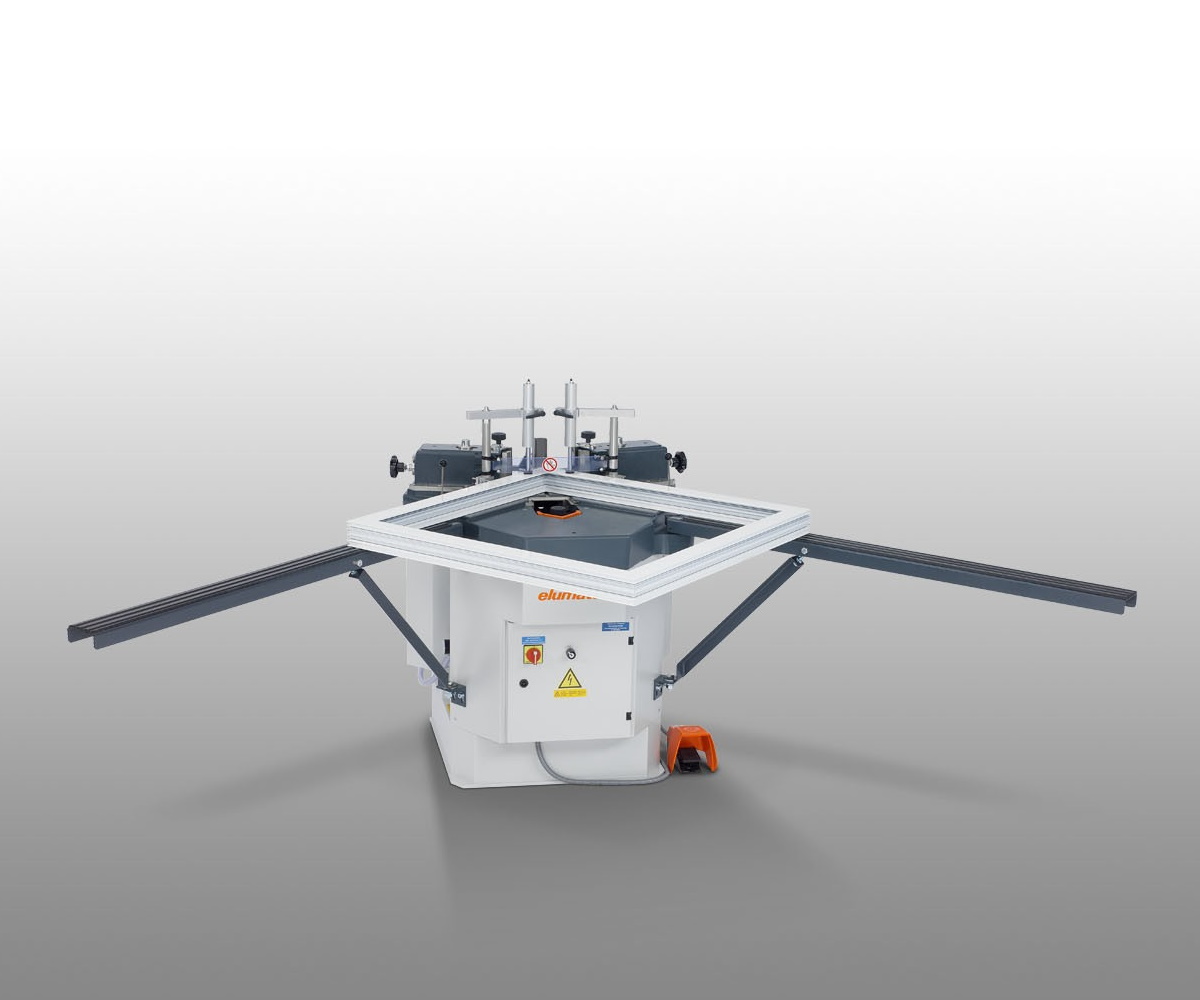

Profile machining centre SBZ 122/75

By: Elumatec India Pvt Ltd| Price | Available on request |

| Category | Equipment |

| Manufacturer | Elumatec India Pvt Ltd |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | Germany |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

Specification -

- Designed for economical and efficient machining of aluminium, PVC and thin-walled steel profiles

- All operations, such as routing, drilling and tapping, are performed while the profile bar is stationary to protect the profile surfaces

- A-axis continuously adjustable from -120° to +120°

- C-axis continuously adjustable from -220° to +220°

- All five axes can move simultaneously with RTCP (Rotation Tool Centrepoint)

- The additional C-axis makes it possible to machine the face of profiles from the left and right

- Linear guides for autonomous clamp positioning

- Better machining results thanks to the intelligent control technology

- Fast positioning of the machining unit with up to 120 m/min thanks to dynamic servo drives

- Tapping without compensation chuck

- The 2-axis add-on unit with the A-axis and C-axis can also accommodate a saw blade with a diameter of 180 mm

- Automatic clamp recognition and clamp positioning

- Ergonomic operation thanks to the advanced inclined bed

- Automatic tool changer with twelve tool tray positions (without tools)

- State-of-the-art 5-axis controller

- The absolute rotary encoder system means no main axis homing is required

- Automatic clamp recognition and positioning prevents collisions

- Power torque routing motor with enclosed speed control for short spindle start-up and braking times.

- Certified, drive-integrated safety functions

- Low power consumption thanks to the intelligent control technology

- DC link coupling in the axis drives for greater energy efficiency

- Uninterruptible power supply (UPS)

- Windows operating system

- 18.5" panel PC, i5 processor, USB ports and network connection

- Simple, stress-free program entry with eluCam on the operating panel, even during operation

- Remote online maintenance

Machine configuration -

- Water-cooled 7 kW, S1 routing spindle

- Autonomous clamp positioning

- Automatic clamp recognition

- Enclosure to protect the operator

- Four horizontal, pneumatic material clamping units

- A material stop on the left

- Tool holder HSK-F63

- Swarf trays for swarf removal

- Minimum-volume lubrication system

- High performance cutting fluid

- Hand-held operator terminal

- Depth gauge

Options -

- Tools

- Tool holders

- Saw blade, 180 mm

- Length measurement on both sides

- Additional stop for overlength machining (left)

- Material reference stop (right) for positioning workpieces with overlength machining

- Green Line cooling unit for the control cabinet with reduced energy consumption

- Barcode scanner

- Protective enclosure can optionally completely enclose the machine on all sides

- Four clamps as standard. Can be equipped with up to eight clamps

- Double clamping and other accessories on request

- 21.6" panel PC, i7 processor

- Note holder

- Sound insulation hood

- Clamping unit optimised to prevent collisions

Technical Data -

|

Max. machining length without profile end machining |

3,851 mm |

|

Max. machining length with profile end machining |

3,525 mm |

|

Traverse path X-axis |

4,176 mm, Vmax. 120 m/min. |

|

Traverse path Y-axis |

1,040 mm, Vmax. 60 m/min. |

|

Traverse path Z-axis |

540 mm, Vmax. 30 m/min. |

|

Direction of machining |

5 (above, behind, front, left, right) |

|

Positioning accuracy |

+/- 0.1 mm |

|

Routing spindle speed |

max. 20,000 rpm |

|

Routing spindle power |

7 kW, S1 (water-cooled) |

|

Tool holder |

HSK-F63 |

|

Tool changing |

automatic |

|

Tool tray positions in the automatic magazine |

12 |

|

Angle head |

No |

|

Disc milling cutter diameter |

120 mm |

|

Saw blade diameter |

180 mm |

|

Tool length (from extent of taper) |

max. 150 mm |

|

Clamp positioning |

autonomous |

|

Clamps |

Premium (with linear guides) |

|

Software |

eluCam |

|

Compressed air supply |

> 7 bar |

|

Power supply |

400 V, 3~, 50 Hz, 25 A |

|

Air consumption per minute |

approx. 185 l with spraying |

|

Total length |

7,643 mm |

|

Depth |

2,171 mm |

|

Height |

3,000 mm |

|

Weight |

approx. 3,800 kg |

Other Products

Post requirements