Heat Treatment Furnace

By: Furnteck Engineers Private Limited| Price | Available on request |

| Category | Heat Treatment Furnace |

| Manufacturer | Furnteck Engineers Private Limited |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | As per order |

| Place of Origin | India |

| Supply Ability | Customization as required |

| Packaging Details | Standard export packing |

| Transportation Details | Road / Ship |

Description

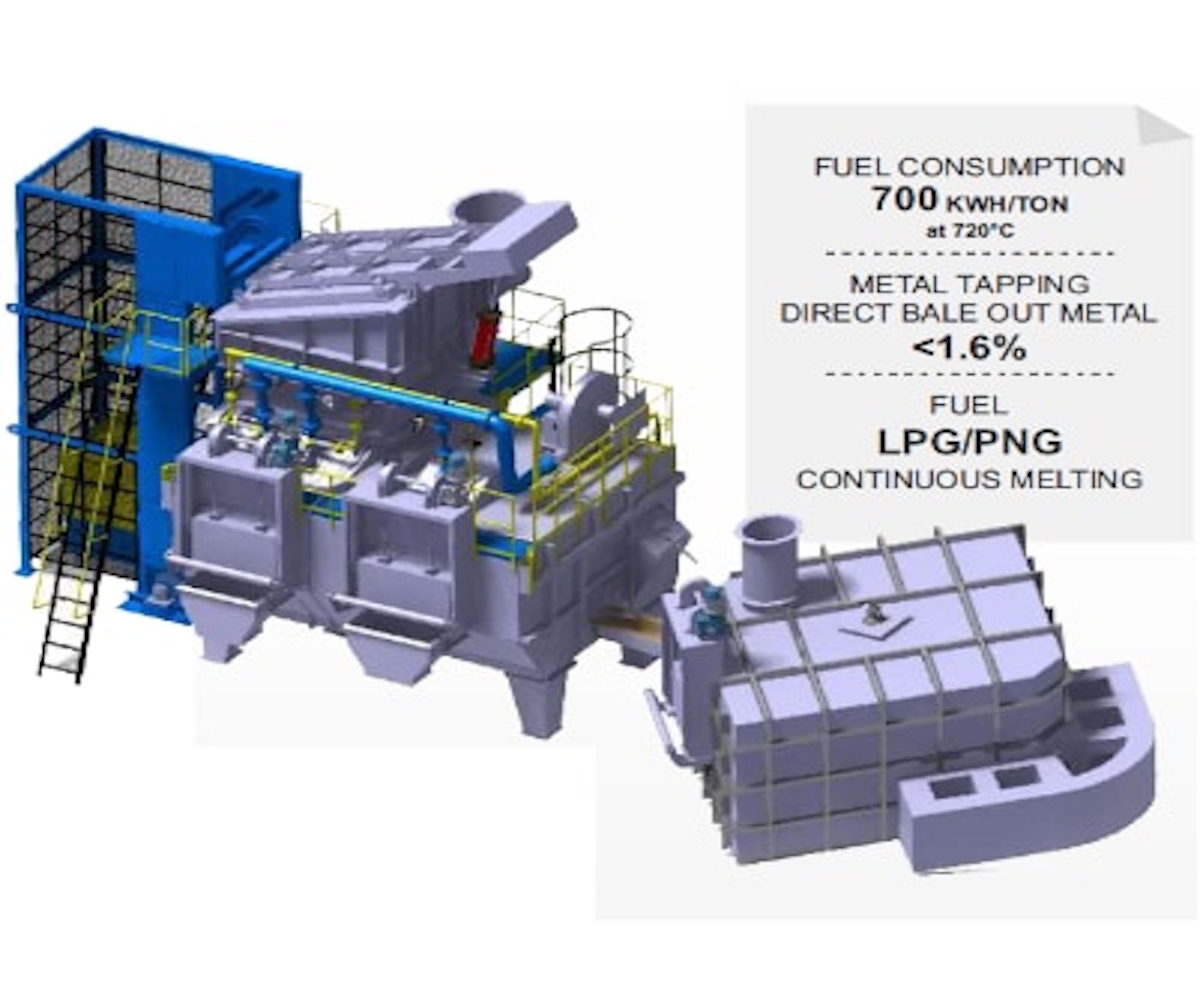

The heat treatment furnace is engineered for the aluminium industry to provide effective heat treatment solutions. With a focus on efficiency, cost-effectiveness and reliability, this furnace is capable of handling a variety of production rates and product mixes. The continuous operation allows for optimal performance, even during periods of lower utilization, ensuring a steady output without compromising quality.

Industries That Use It:

Heat treatment furnaces are widely utilized in industries that require precise heat treatment processes, particularly in the aluminium sector. Manufacturers of automotive components, aerospace parts and various other applications that demand high-strength aluminium alloys benefit from this furnace's advanced features and reliable performance.

How It Works:

A heat treatment furnace operates through a carefully controlled heating process that subjects aluminium parts to a series of temperature cycles. The furnace maintains uniform heat distribution, which is essential for achieving the desired mechanical properties of the aluminium. This process typically involves solutionizing, quenching and aging steps that enhance the strength and durability of the alloy.

The furnace uses a combination of gas and electric heating methods to ensure optimal energy consumption and effective heat recovery. The centralized control system allows for continuous monitoring and adjustment of parameters, ensuring consistent results throughout production runs.

Key Features:

Fully customized solutions tailored to specific customer requirements.

Fully automatic operation for ease of use.

Uniform heat distribution for consistent quality.

Centralized heat recovery system to enhance energy efficiency.

High-quality refractory materials for durability.

Continuous monitoring through an advanced supervision system.

Specification:

Heating Method: Gas-fired or electrically heated options available.

Temperature Range: Up to 600°C (varies based on specific requirements).

Production Capacity: Customizable based on client needs.

Control System: Advanced centralized control with monitoring capabilities.

Refractory Lining: High-quality materials for enhanced thermal efficiency.

Customization Options: Sand removal system, cooling systems, etc.

Benefit:

Energy Efficiency: Designed to operate efficiently even during low utilization.

Cost-Effective: Reduces operational costs through energy recovery systems.

Flexibility: Accommodates various production rates and product types.

Reliability: Built to provide consistent performance over long operational periods.

Enhanced Product Quality: Achieves superior mechanical properties in treated aluminium products.

Other Products

You may be interested in

Post requirements