Billet Casting Technology

By: ALMEC TECH| Price | Available on request |

| Category | Aluminium Casthouse Equipment |

| Manufacturer | Almec Tech |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | 120 Days |

| Place of Origin | Italy |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

Many tonnes/Ann of aluminium are processed with DC casting methods for the productions of billets.

These solid geometrical elements are largely involved for the extrusion of profiles, then used by various industrial sectors, as transportation, automotive, packaging, construction and aerospace, for their productions.

The role of Almec Tech is providing technology and high precision equipment for the casting process of billets.

The dimensions of the desired elements are possible to be adapted to different necessities. AT technicians can realize different diameters and lengths to comply to the specificity of the cast house project.

The technology for the production of billets have the following advantages:

●RELIABILITY, of the materials that allows a long duration of use and a reduced maintenance;

●BILLET QUALITY, minimal shell-zone, uniform grain and according to international standards;

●USER FRIENDLY for easy maintenance;

●ENERGY SAVING.

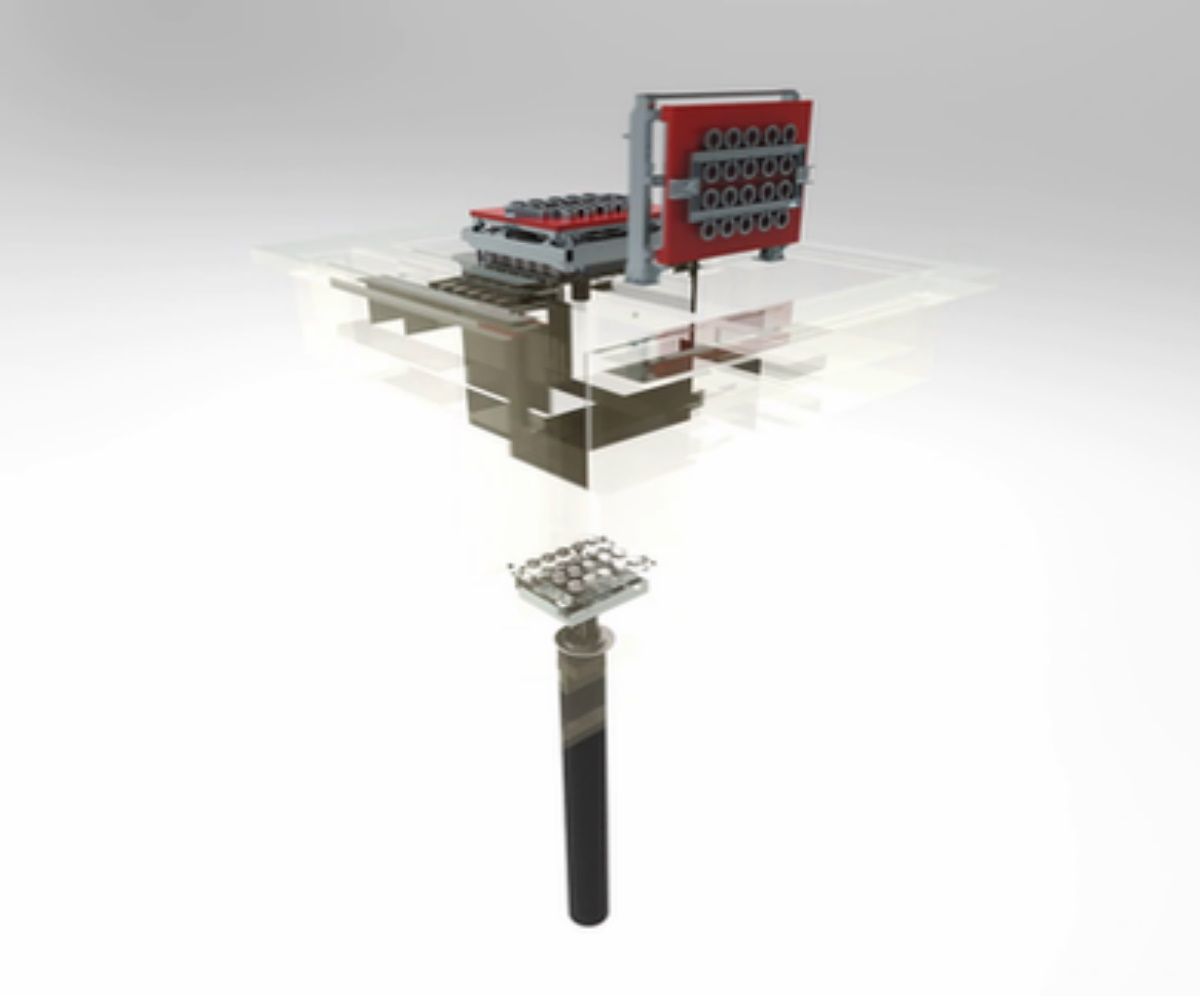

A number of 6 equipments, are specificly dedicated to billet casting process. They represent the core of the casting machine.

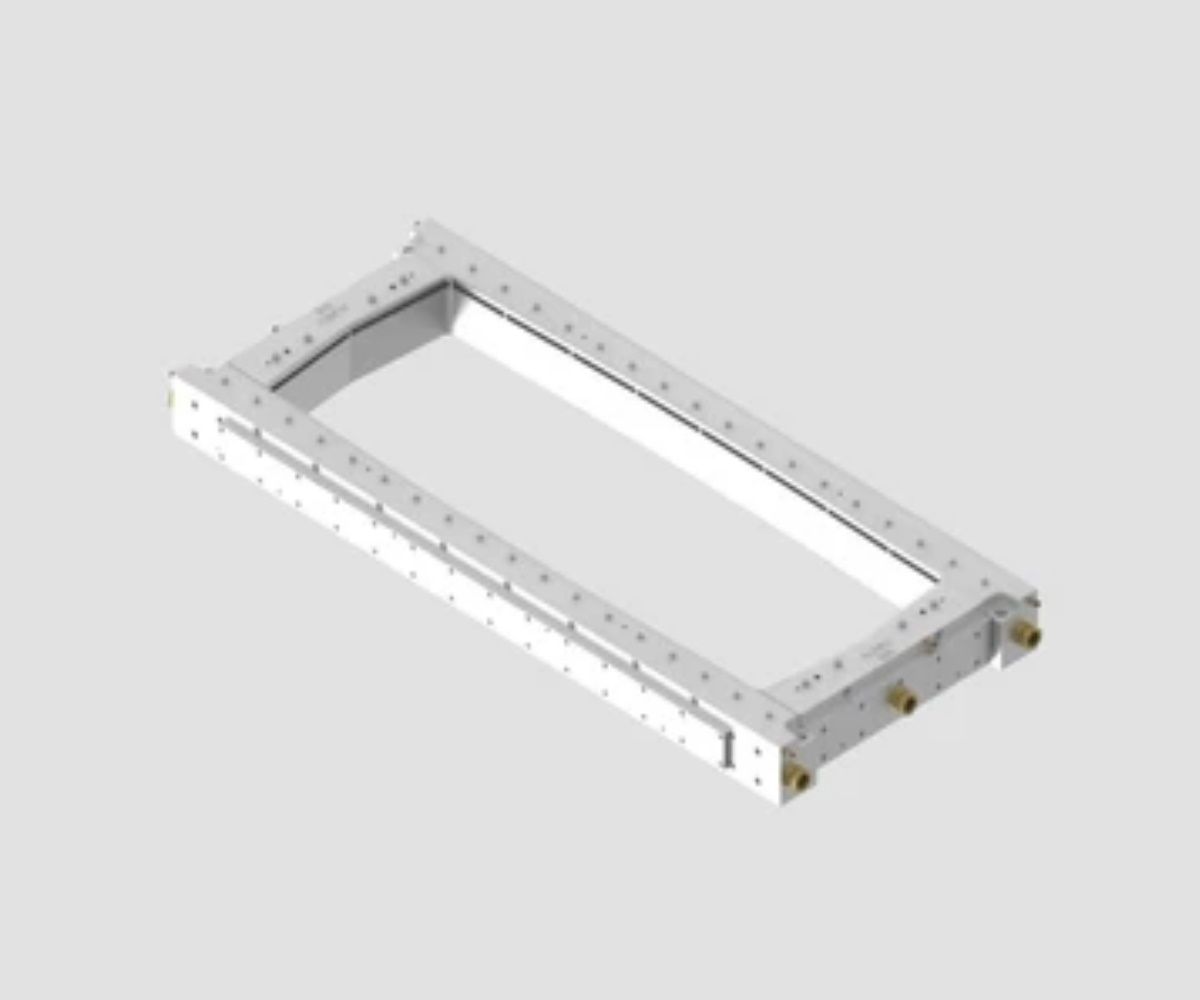

1) Starting head holder frame

2) Moulds holder frame

3) Distribution launder

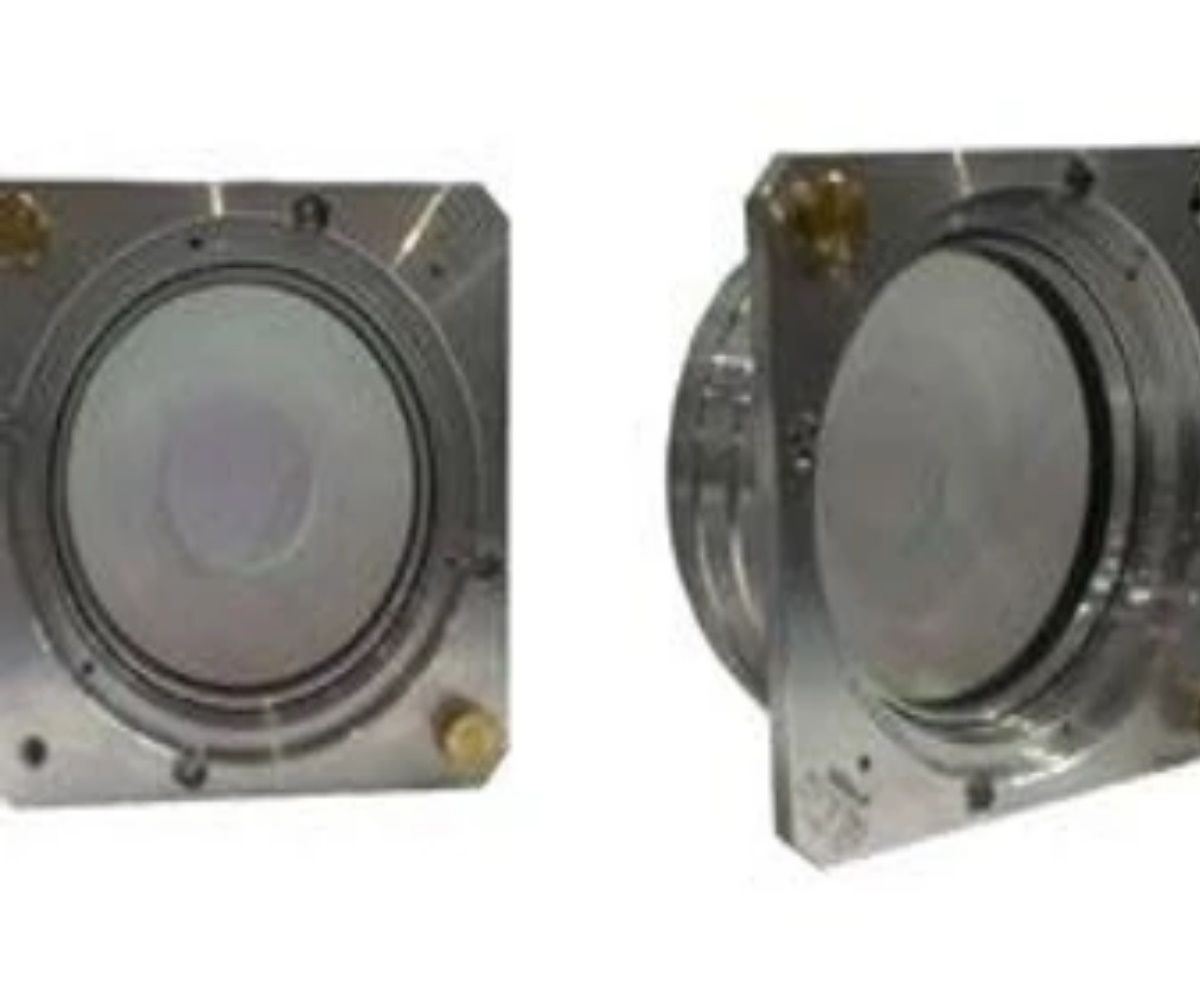

4) Moulds for billet

5) Staring heads for billets

6) Service station for maintenance

Other Products

Post requirements