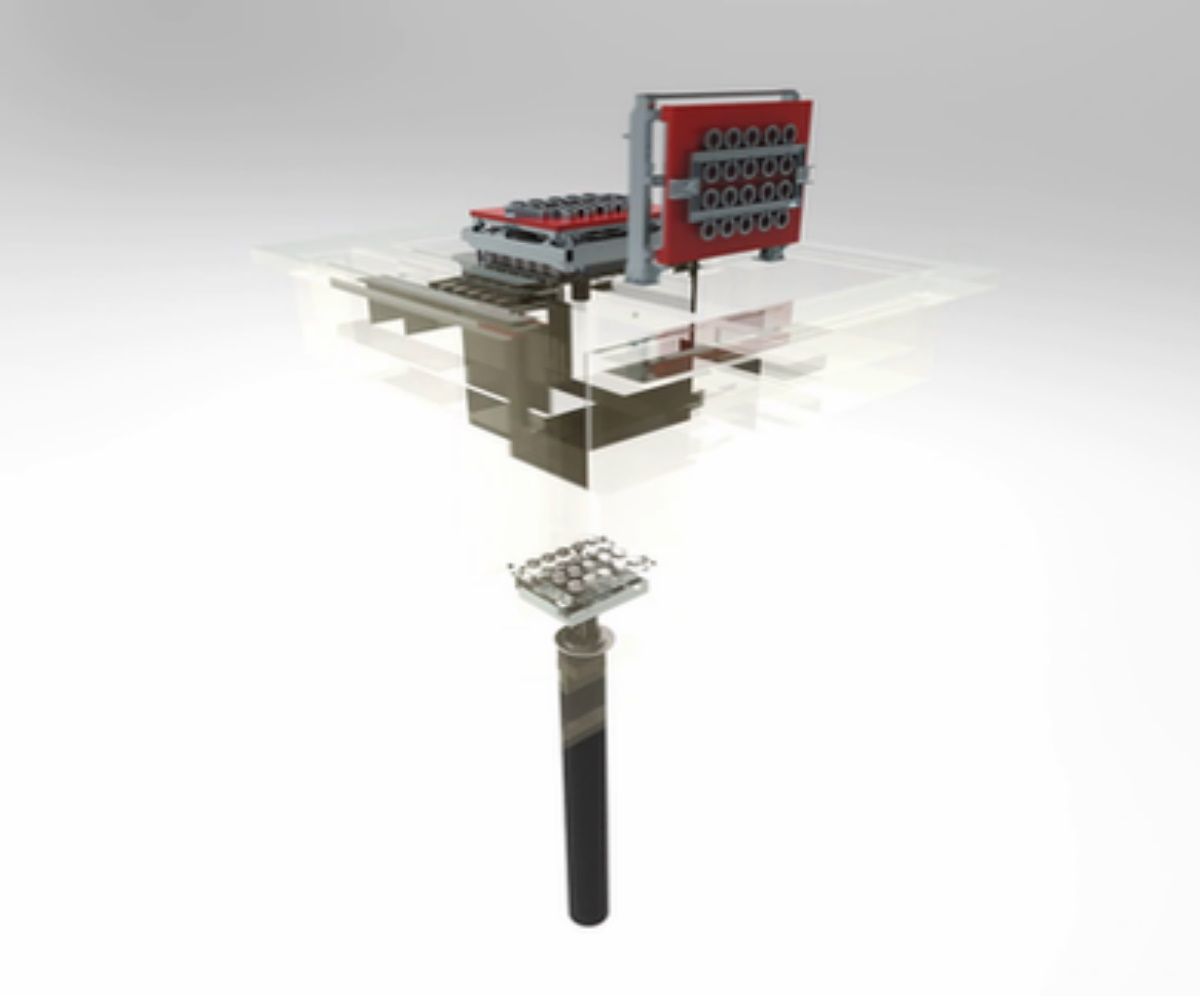

Slab Moulds

By: ALMEC TECH| Price | Available on request |

| Category | Aluminium Casthouse Equipment |

| Manufacturer | Almech Tech |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | 120 Days |

| Place of Origin | Italy |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

Adjustable or Fixed Mould:

The mould is the master where the final shape of the slab is originated. The geometric element is provided of an internal water circuit for cooling and solidification as “water blade” to make the flux and the water distribution more uniform. On the mould is applied a thin layer of lubricant distributed through the graphite, in order to lubricate correctly during cast.

Two different formats of mould are available:

WALL C MOULD: It is designed to be versatile and performing for the production of Soft and Hard Alloy. It is made up of four elements in aluminum alloy, machined on high precision numerical control machines, joined together by means of special fasteners. Its first contact wall in aluminum is lubricated through a system of graphite inserts.

The secondary cooling consists of supply chambers in series to favor a homogeneous distribution of the water in all areas of the mould. The balancing of the flows is proved to be of primary importance for the metallurgical characteristics of the product.

The dimensional variation of the mould format can be Proposed in the types:

- Modular with variable length;

- Fixed modular.

ACS GH MOULD: It is designed to be versatile and performing for the production of Soft and Hard Alloy. It is made up of four elements in aluminum alloy, machined on high precision numerical control machines, joined together by means of special fasteners. The mould ACS GH is made of high quality graphite inserts which guarantee better surface and structural results. A special treatment is carried out on the graphite surface to improve its heat exchange, thus increasing the performance of the mould with a consequent improvement in cortical segregations.

The dimensional variation of the mould format can be performed manually, usually for existing systems or automatically, by performed by positiong.

Proposed in the types:

-Modular with variable length. It guarantees greater production flexibility for formats of various thickness and width, according to specific needs;

-Fixed modular, for products with standard dimensions.

Other Products

Post requirements