Aluminium Rod Feeder Machine

By: ALMEC TECH| Price | Available on request |

| Category | Wire Rod Equipment |

| Manufacturer | Almec Tech |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | 120 Days |

| Place of Origin | Italy |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

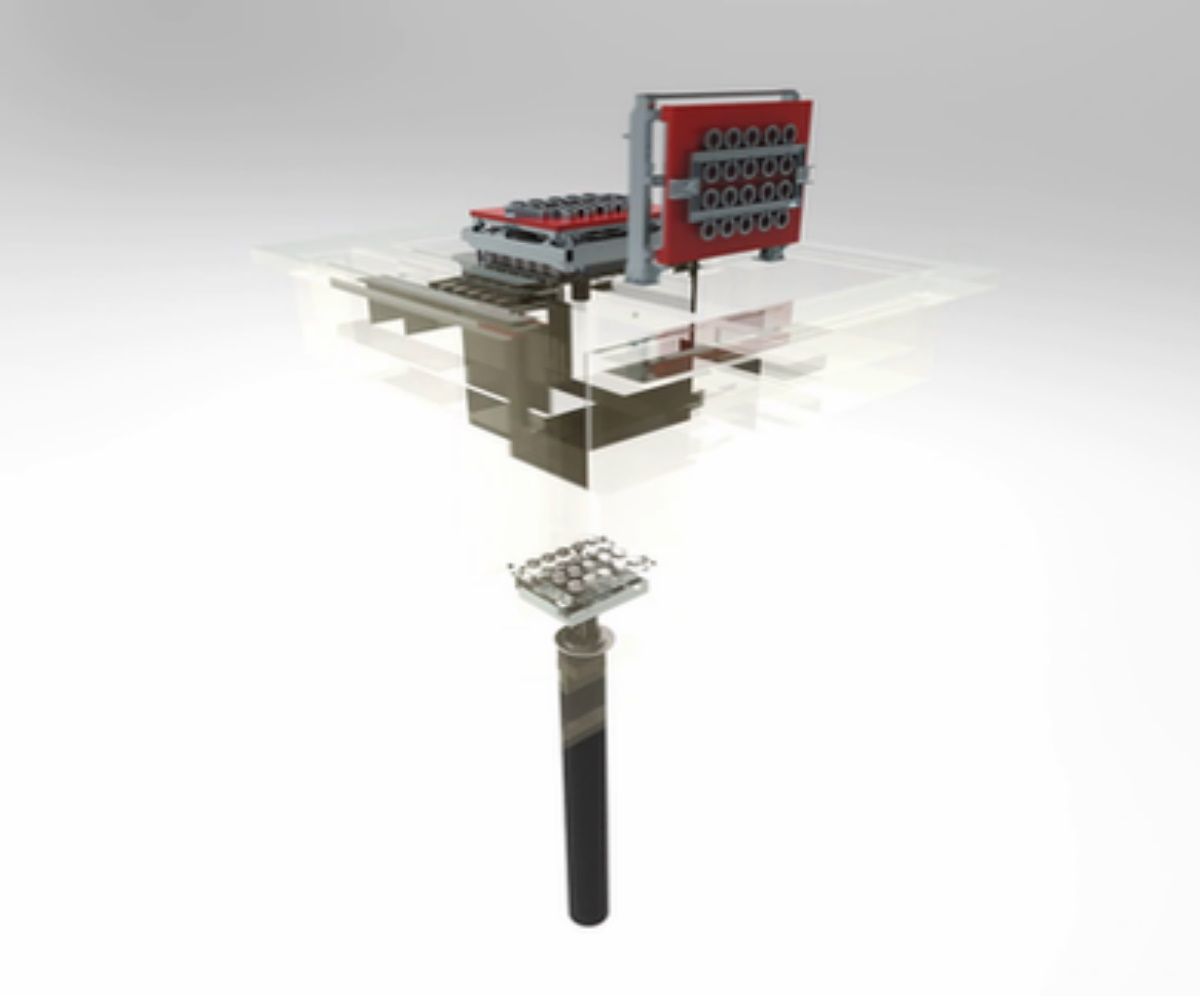

Application for refining the grain during the aluminum casting process, ensuring an optimal final result.

Thanks to the experience gained and continuous research, Almec Tech offers a fully automated aluminium wire rod feeder, useful for waste optimization and for a simple and effective management of boron titanium wire, by means of your machine's PLC or by an operator.

The application is composed as following:

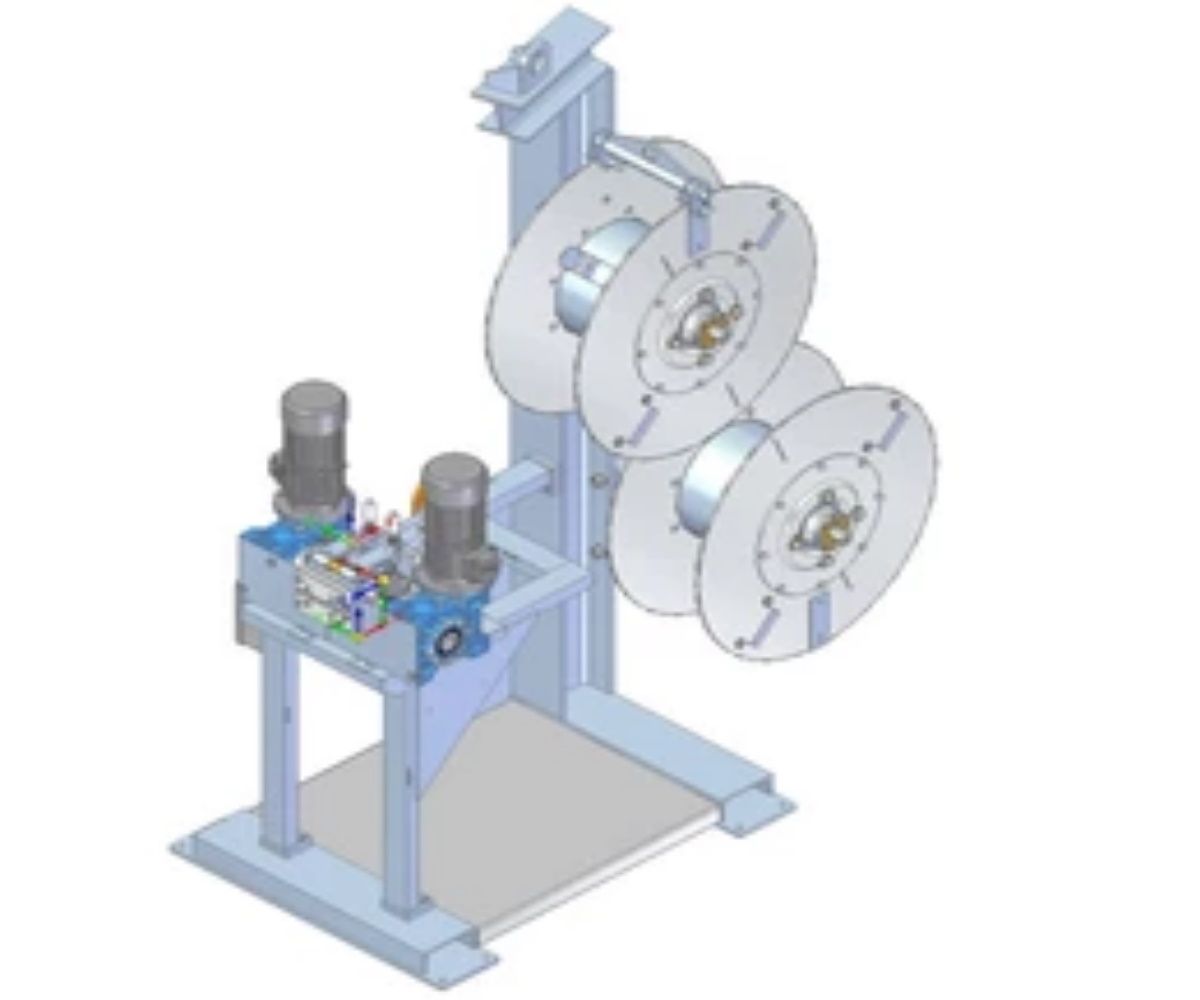

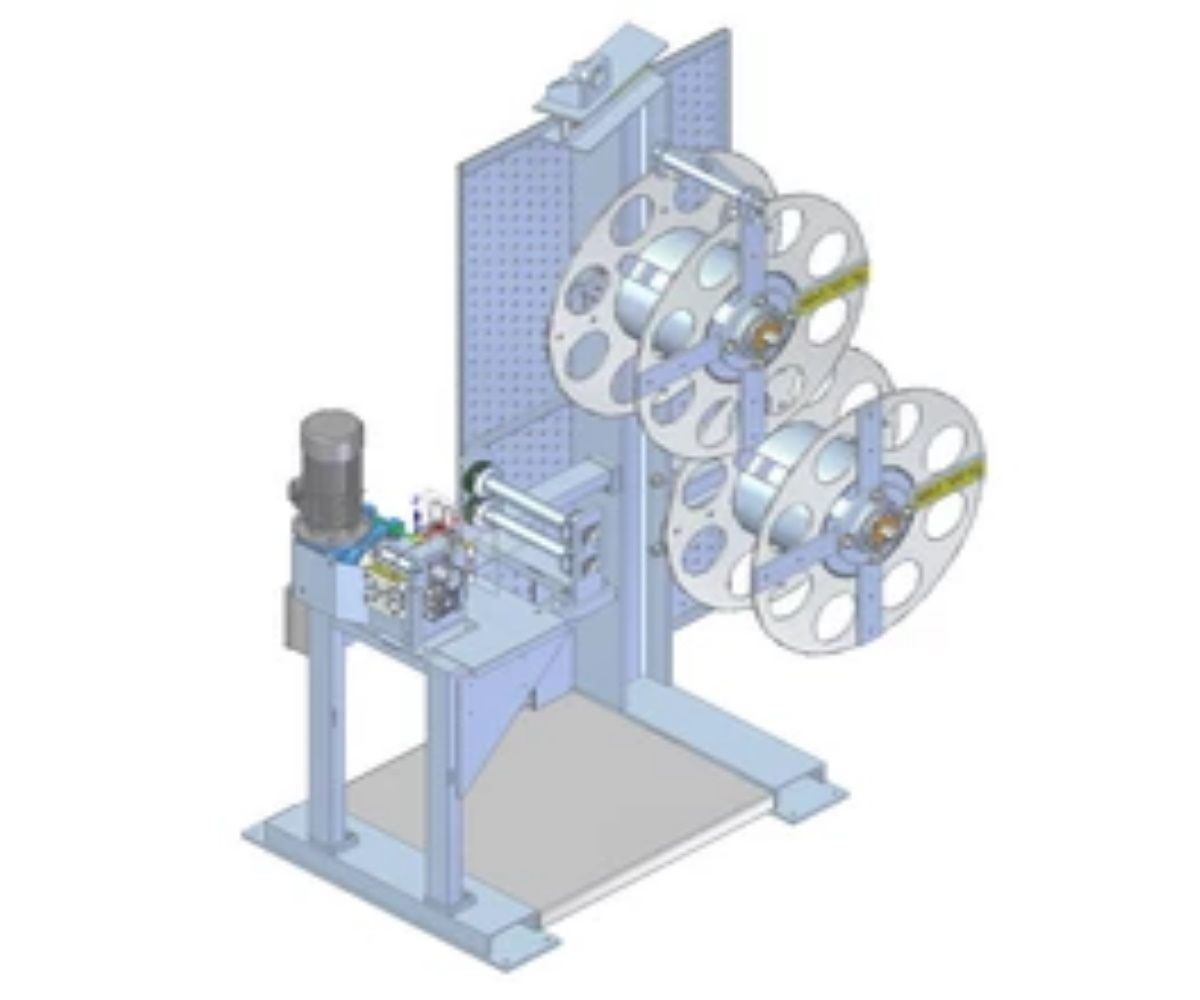

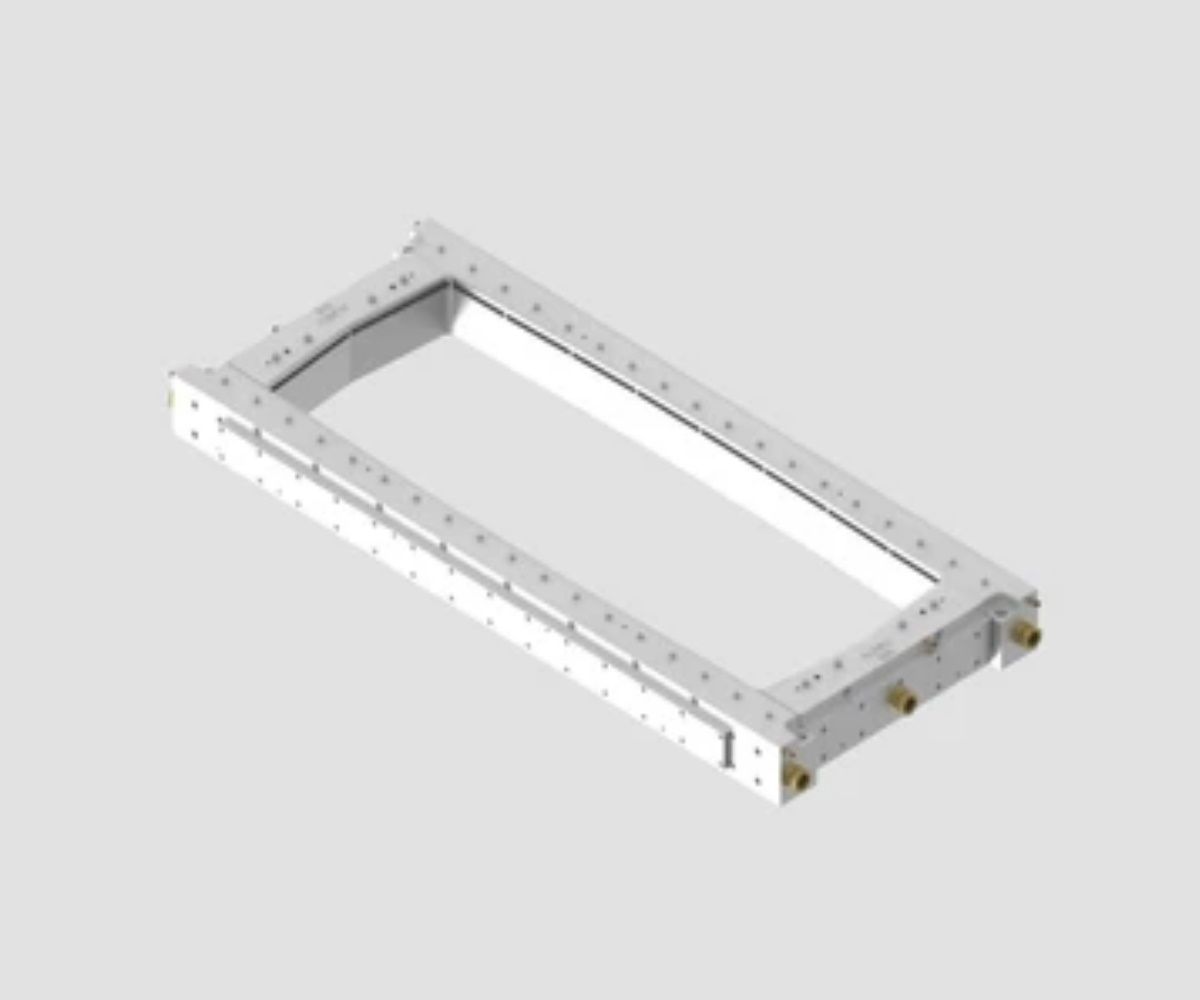

1) Mechanic support structure, providing a hanging surface for spool's coils ;

2) Feeder group provided of the powering engines, and of rod guidance device for speed, competed of electrical wiring and control box with jogs;

3) 1 or 2 Spools of titanium wire.The spool is connected to the feeder group and powered by the engines;

4) Electrical panel for operations control;

5) 1 or 2 Engines. The wire speed is determined by the indications about the volume of the processed metal and the % of alloying desired. The option of using n.1 engine makes the two wires will move consequentially: when the first finishes, the second starts. The option of using n.2 engines makes the wires to move independently and simultaneously: when the first wire finishes, the second doubles its speed

Advantages:

- Fully automated;

- Automatic management of alarms, partial and total meters of yarn consumed;

- Easy use of the operator on the machine;

- Excellent results of the refining process;

- Prevents the wire rod wasting.

Other Products

Post requirements