Complete Aluminium DC Casting Machine

By: ALMEC TECH| Price | Available on request |

| Category | Aluminium Casthouse Equipment |

| Manufacturer | Almec Tech |

| Min Order Quantity | 1.00 Unit |

| Delivery Lead Time | 120 Days |

| Place of Origin | Italy |

| Supply Ability | Customization on Requirement |

| Packaging Details | Standard Export Packing |

| Transportation Details | Road/Ship |

Description

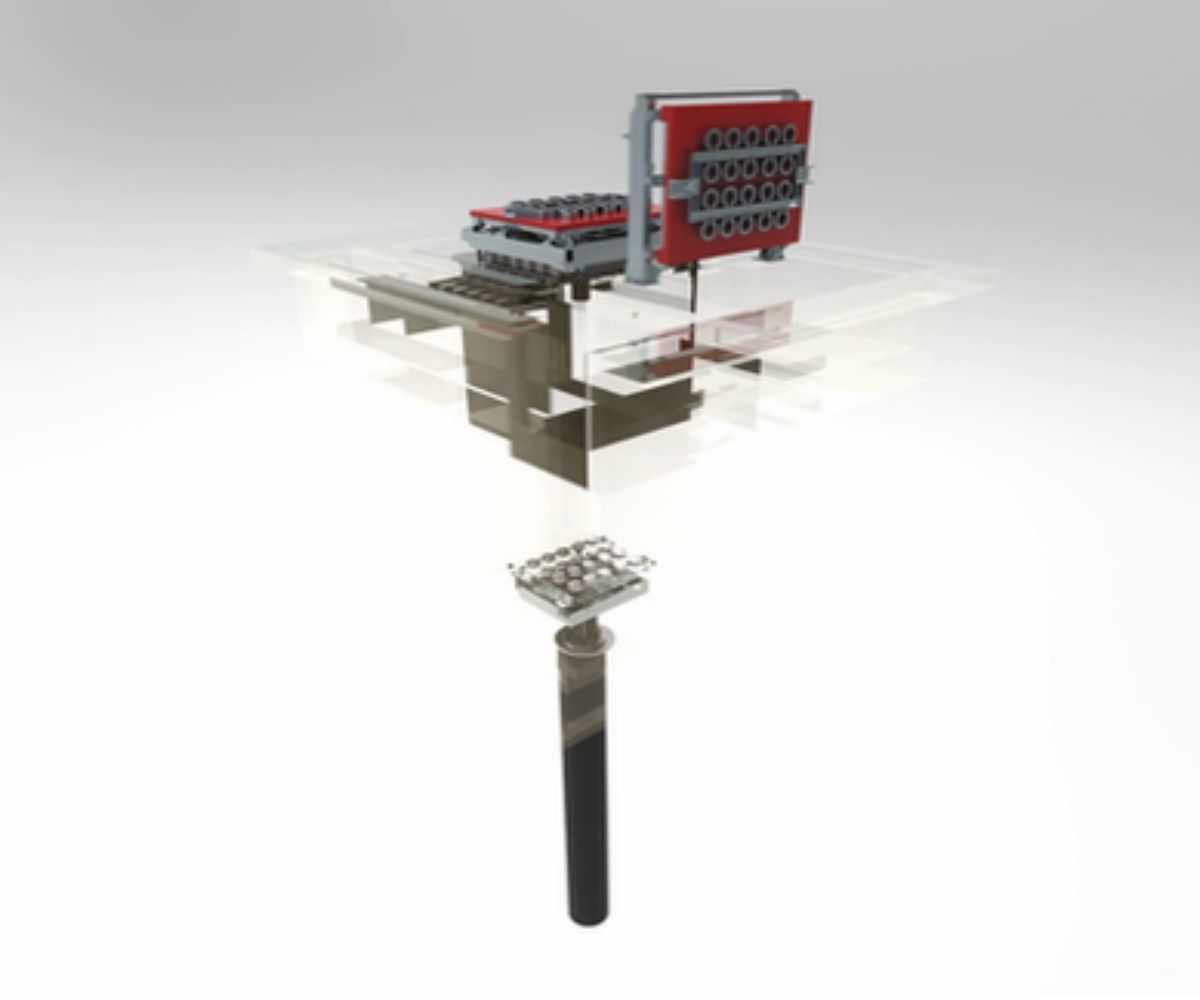

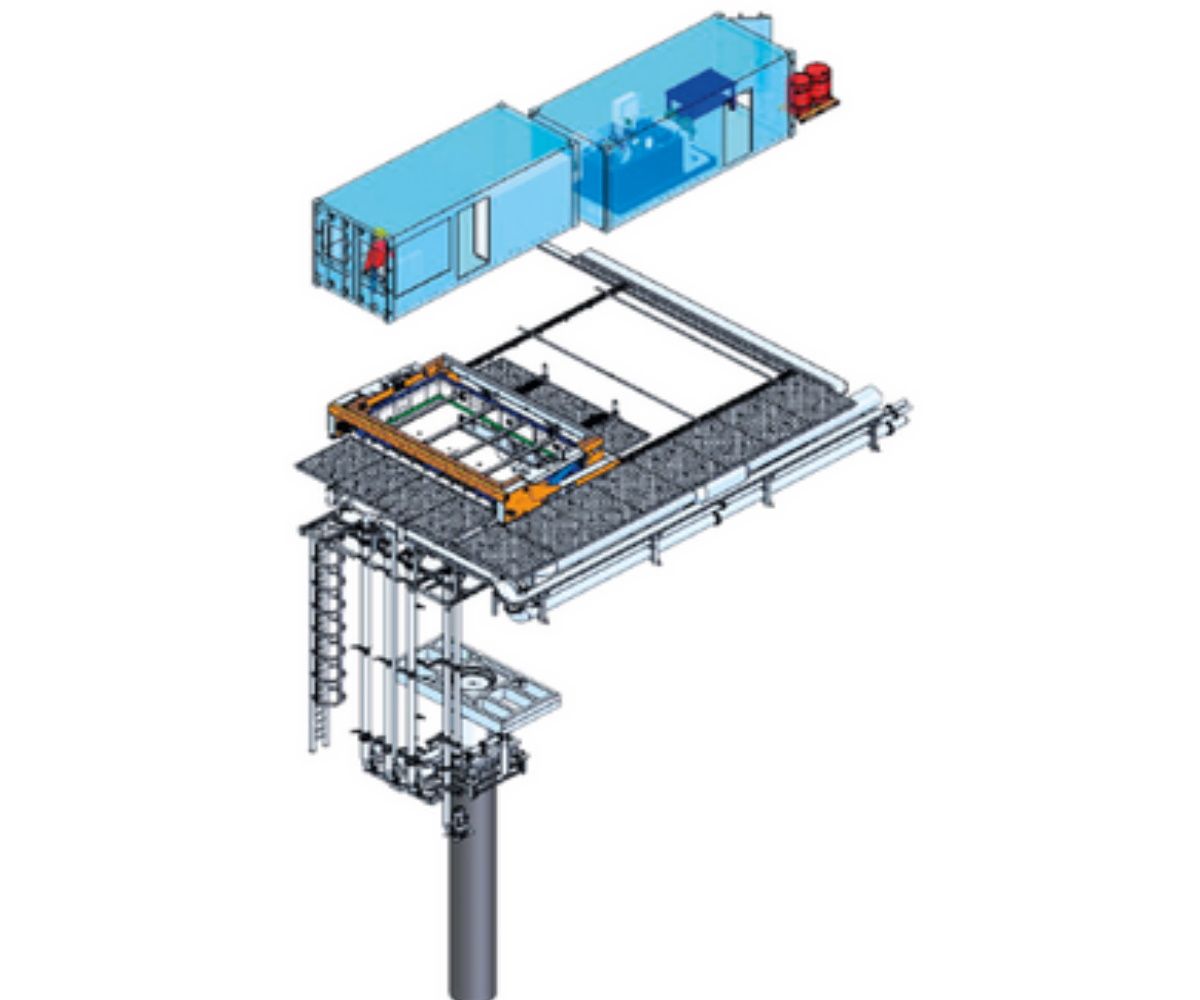

Almec Tech DC Casting Machine is a complete semi-automatic plant, designed and assembled for the production of slabs and/or billets of various dimensions and length, aluminium alloys for the industry of vertical semi-continuous aluminium casting process.

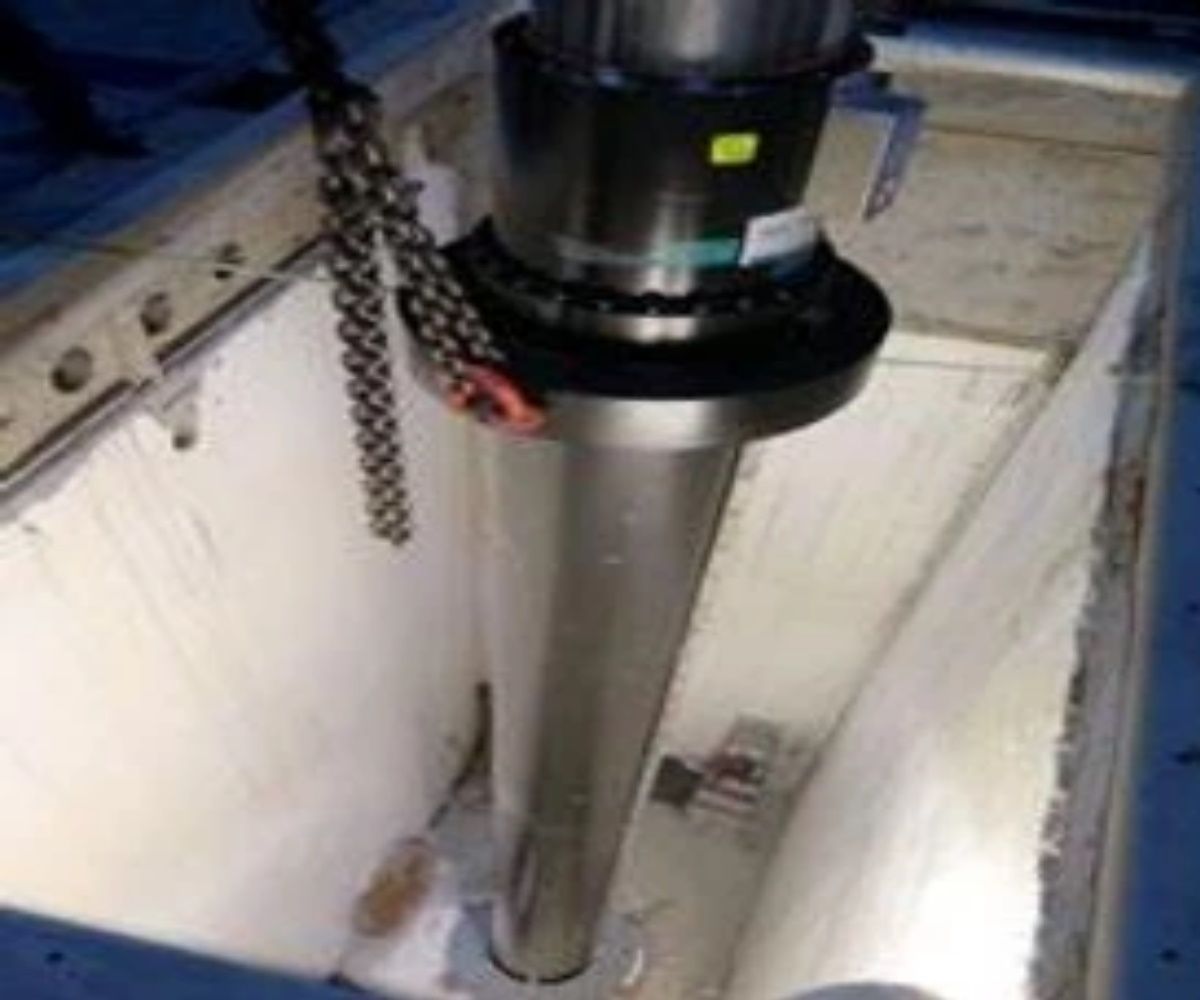

The intended use of the machine for vertical semi-continuous casting of aluminium type is to cast, into a mould shell, the aluminium coming from the furnace, cooled through water. The descend is guided by a casting cylinder self guided. The whole system moves fully automatically with the highest safety application.

The equipment composing the machine are:

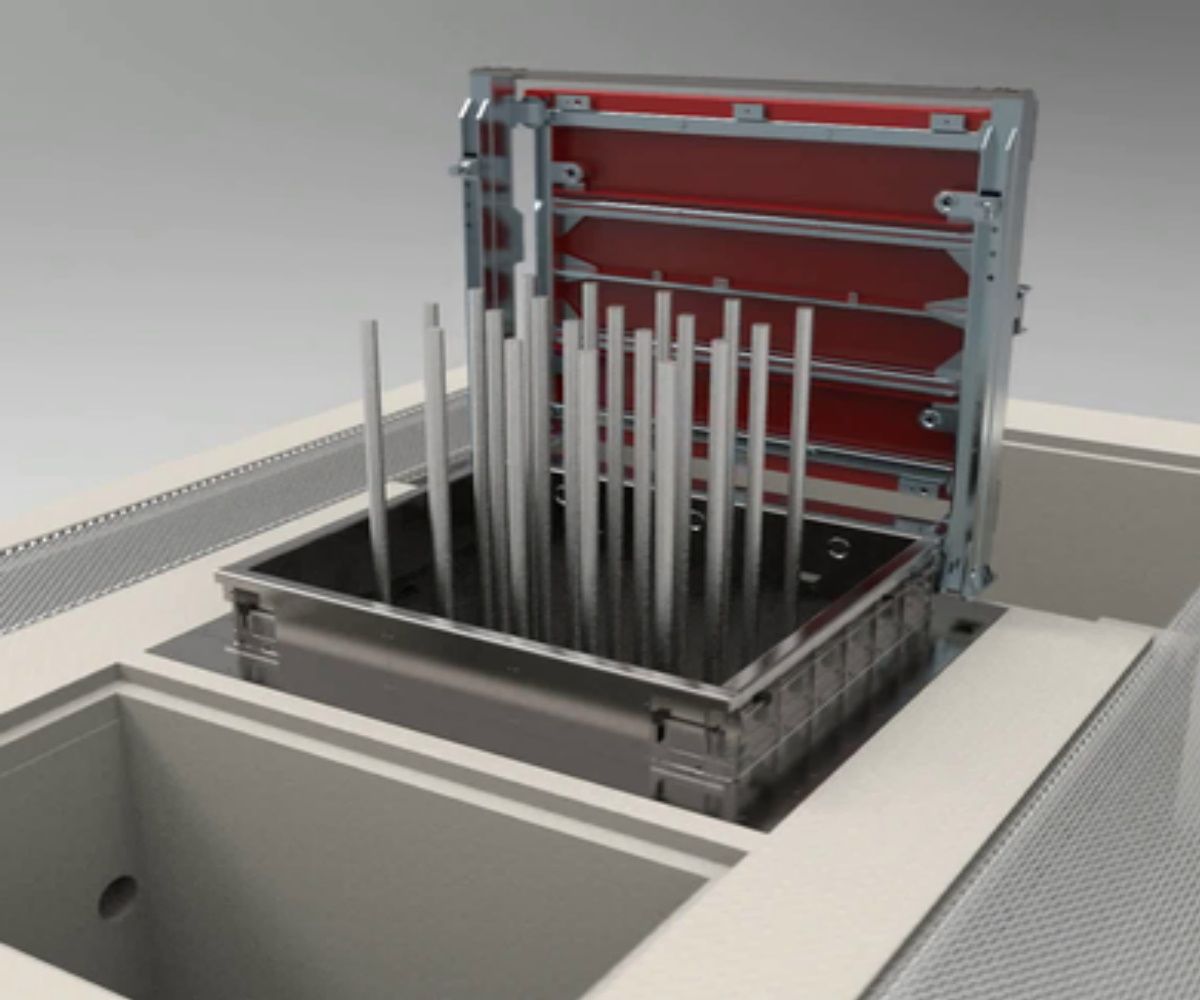

1) Casting cylinder, responsible of the vertical descent movement, which represent the moment when the billets and/or slabs is taking shape;

2) The hydraulic power unit, responsible of the movement of the casting cylinder, the emergency valve (installed on the panel control room) and other utilities of the machine;

3) Tilting equipment holder carriage, which supports and moves the slab and/or billet casting equipment on rails (or roads), moving them from the preparation/maintenance position to above the casting pit;

4) The control and technical rooms, where all the machine's control panels are placed;

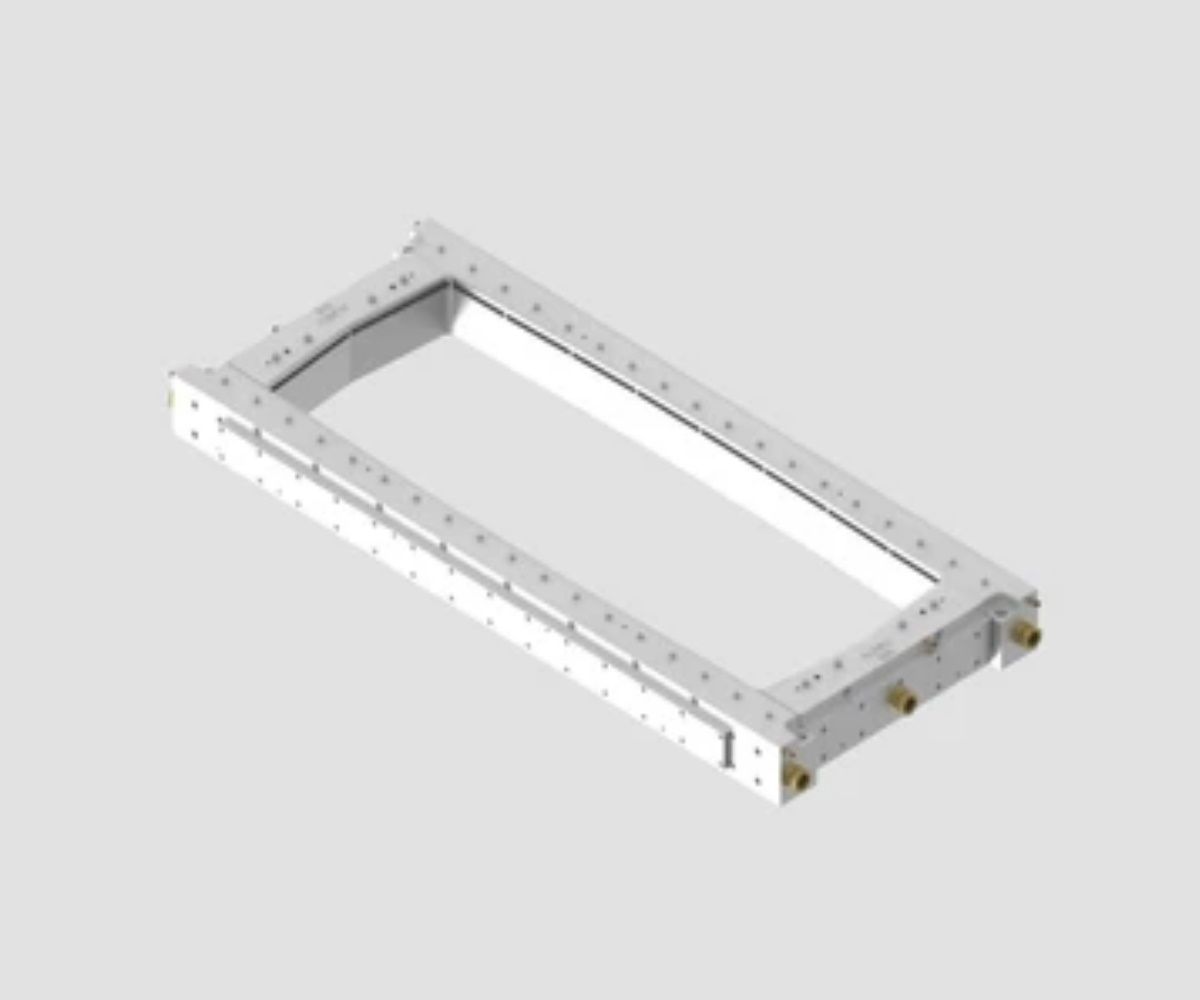

5) Pit edge with lights and tilt grid support, delimiting the edge of the casting pit acting as a “splash guard”;

6) Water pumps, for drainage and re-circulation of the water used in the cooling process;

7) Service station for maintenance.

jkjk

jkjk

Almec Tech make service and maintenance of dc casting complete plants and machines, carrying on external and deep cleaning, restoration or substitutions of damaged parts and components, and more.

Other Products

Post requirements